Named Looop, the new apparatus debuted on October 12 in one of the brand’s Stockholm stores, offering customers a chance to see how their old garments are reborn.

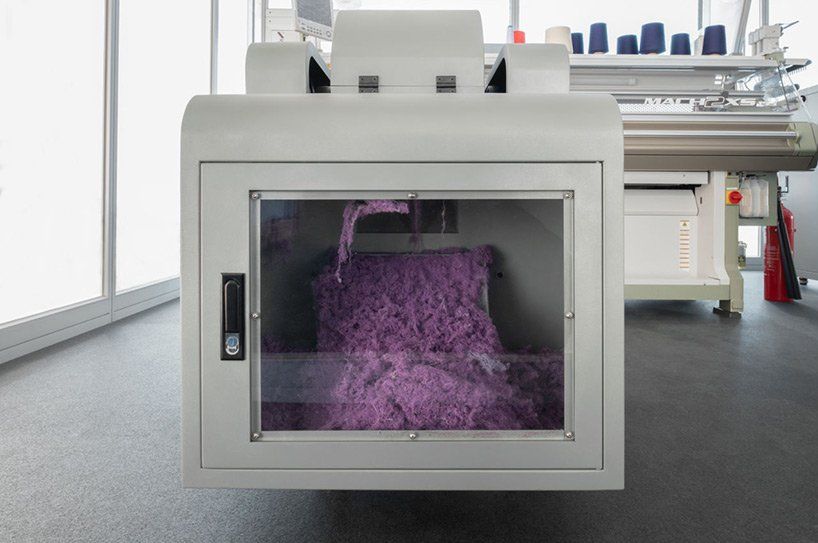

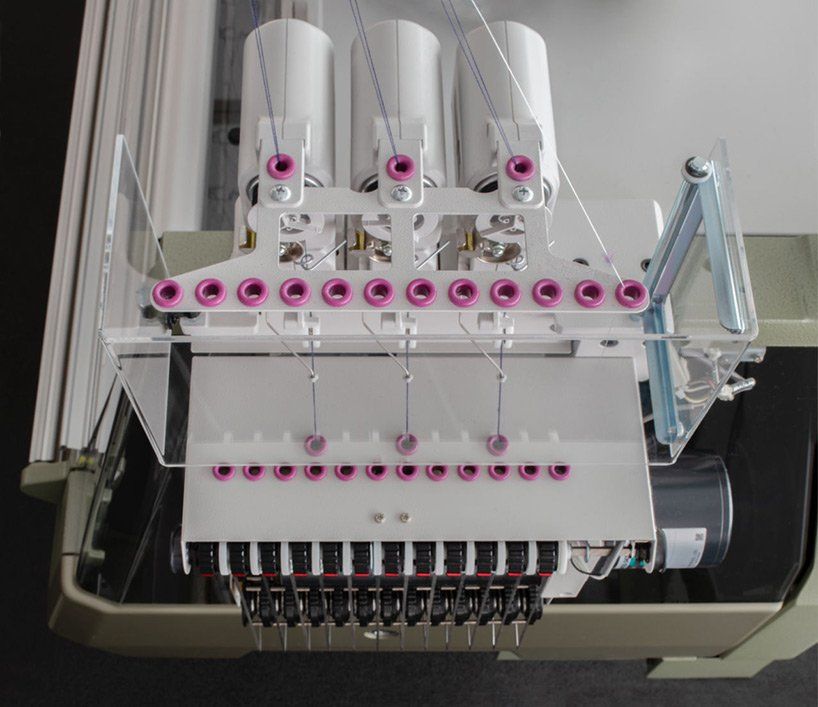

H&M’s long-term goals include developing a more sustainable business model: the machine presented recently can be one of the milestones of this plan, manufacturing a completely new piece out of our unwanted garments in eight steps. During the almost five-hour process, the old piece of clothing undergoes ozone cleaning first, and then it is shredded down into small chunks of fabric fibers. Then extra virgin material is added for strength, and the resulting clean fiber mix is straightened into a fiber web and then pulled into slivers. As a next step, multiple fiber slivers are combined to create thicker slivers, which are then spun into yarn, which Loop finally knits into a new, ready-to-wear design.

The technology has been developed by Hong Kong Research Institute of Textiles and Apparel (HKRITA) and H&M Foundation jointly.

H&M Looop | Web

Source: designboom

Highlights of Hungary 2020 | Miki357

Winery in a Renaissance environment | ORA