Even though summer is over, there are brands and creators who work on saving the summer heat for us. Sunny afternoons, the feeling of exuberance, and the freedom of the beach can all be condensed into a box, or more precisely an ice cream mold, if you do it wholeheartedly. In the current episode of our Behind the scenes series, we headed to Nagytarcsa: come with us to the Anjuna factory!

Many stories begin with someone starting in gastronomy as the offspring of a confectioner or chef dynasty. The story of József Szalay and the Anjuna brand is much more unusual: Joe, as everyone calls him, was a professional online poker player who spent days on end honing his skills and pressing his luck with cards. But in the mid-2010s, he and his business partner at the time, Milán Szabó, got to thinking that maybe it was time to make a change and do something that would give them a more lively connection with others and that while also creating something of value for the people. During a holiday spent on the coast of Anjuna, India, the idea for a start was conceived—the inspiration for the ice creams came from the then popular ‘ice pop’ they saw in the US.

“At first, we were more business-minded, but then very quickly we got sucked into the world of ice cream.”

They were certain about a few things. They wanted to make a product that was incredibly delicious, made from high-quality ingredients, free from major allergens, but also playful and easy to love. Lacking expertise, they turned to the best for advice and training, ordered the necessary machinery and ingredients, leased a plant, and got to work. Things escalated quickly, and in 2016 they opened their shop on Lövőház Street in Budapest, followed shortly after by the Sas Street shop. The easily recognizable elephant-logo served as a signpost for many: this stylish design was done by Szani Mészáros and the DekoRatio Studio.

“When we opened our first shop, we stood there with six months of work and experimentation behind us and the desire to become Europe’s favorite ice cream brand. But at the same time, we weren’t even sure if the public on Lövőház Street would like it.”

In 2017, they were chosen as official partners for the World Aquatics Championships, a bolt from the blue for the small, albeit growing team. They stood their ground. Continuously pushing forward, they have since been involved in a number of charity projects, for example, as huge doggy-enthusiasts, they partnered with MFÖEK (standing for Everyone Adopt a Puppy!—the Transl.) They also launched the Anjuna a Kutyákért Alapítvány (or Anjuna for Dogs Foundation—the Transl.), whom we can support by buying their Pupsicle made of bananas and peanut butter, while also making our pupper happy. In 2019 came Interspar’s Hungaricool campaign, which will have them in all the chain’s freezers in Hungary by next summer, but you can also buy their goodies in other organic shops, delis, and the shop on Pozsonyi Street. When the epidemic hit, Joe’s old friend Attila Vincze joined the team, with whom they have been building the business ever since and without whose help Anjuna would not have survived 2020.

“We use premium ingredients. Some we import directly, but most of it is sourced from partners who are also suppliers for the best restaurants in Hungary.”

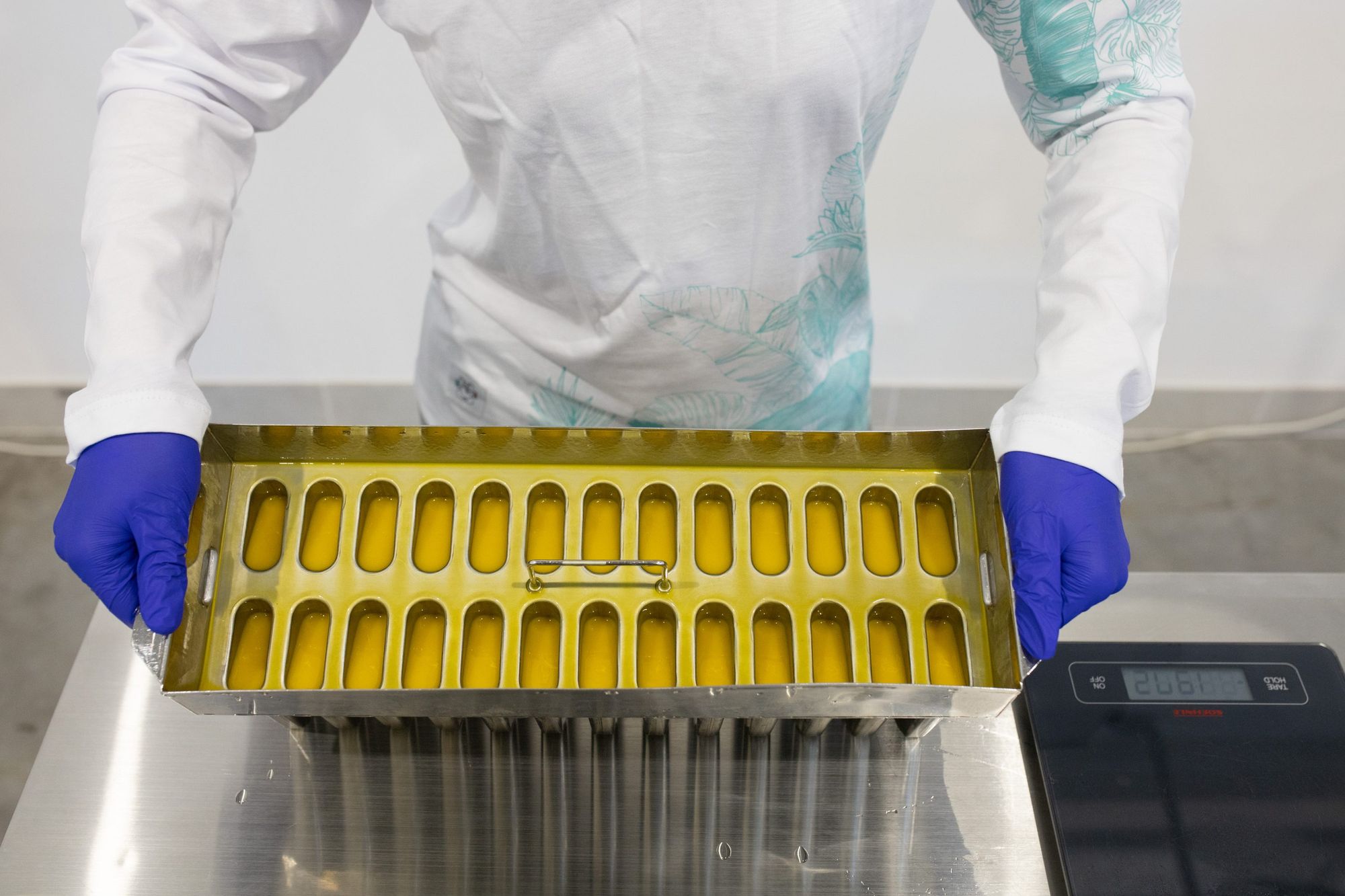

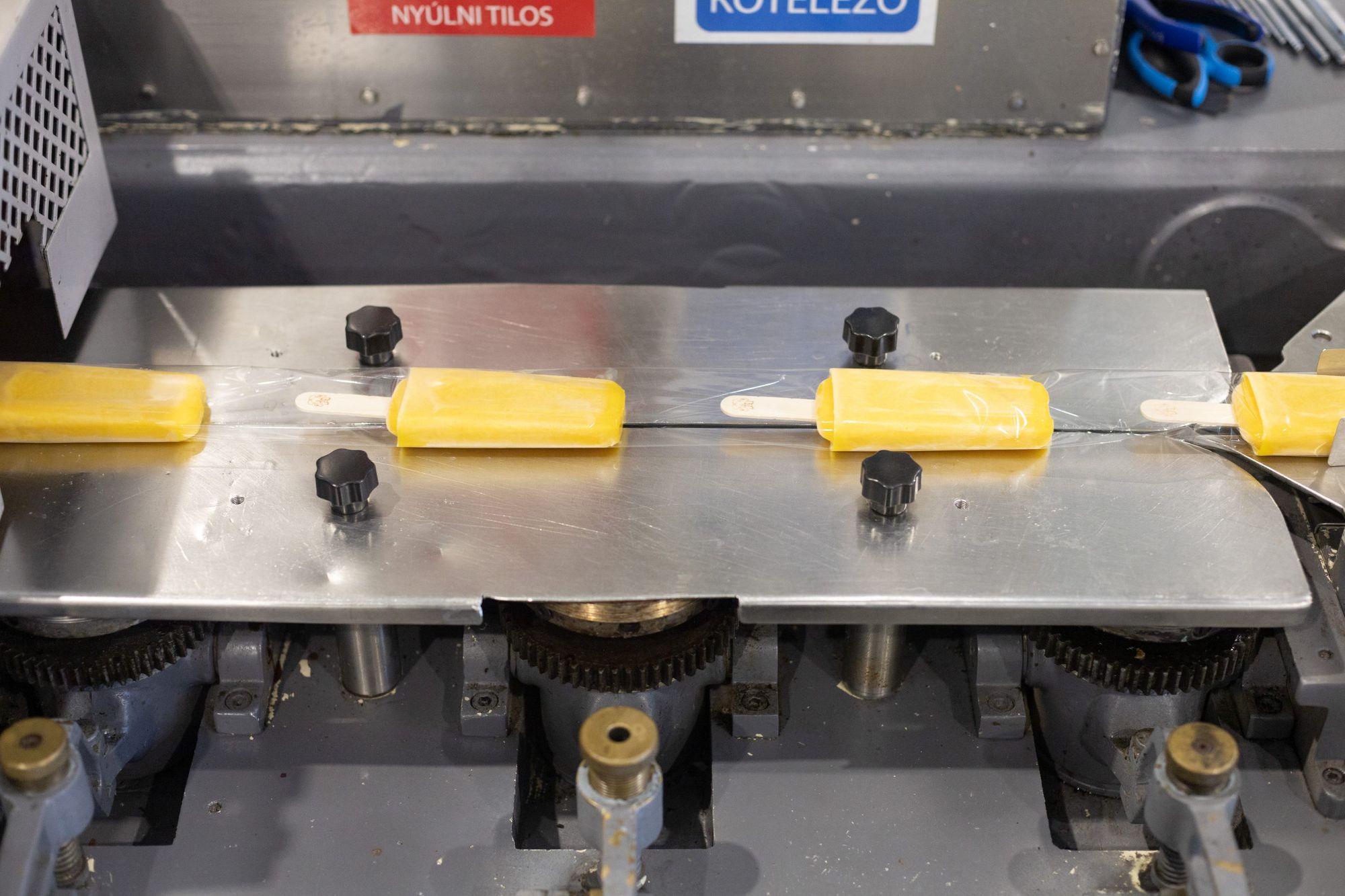

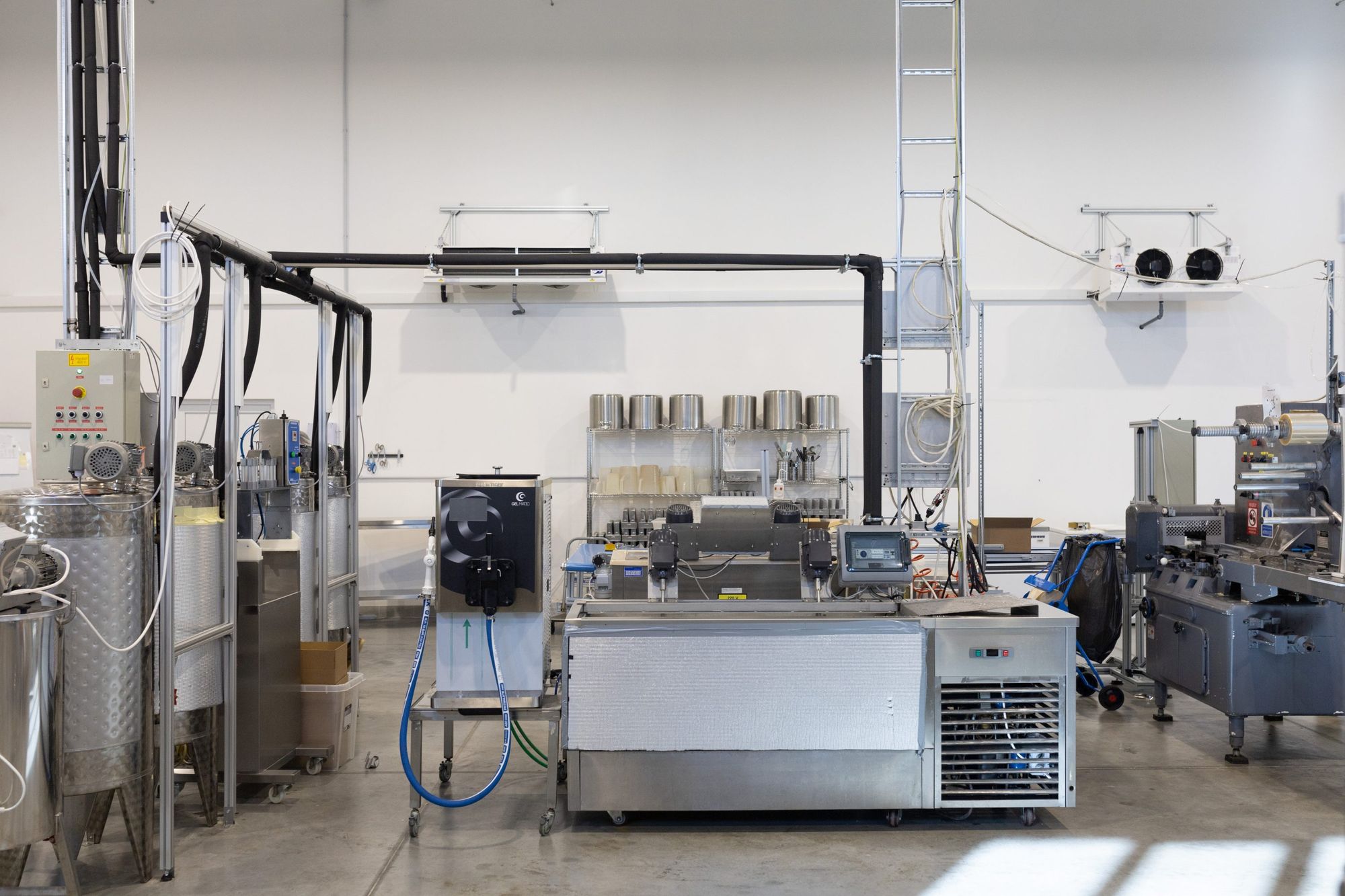

In February 2022, they took a deep breath and relocated the plant from Káposztásmegyer to Nagytarcsa, to a new facility of 800 square meters. Here, 6+2 people work during the season to ensure that the ice creams reach every corner of the country. In principle, they make one flavor a day, but this can be increased to 4-5 if necessary. First, the ingredients are measured out, which consist mostly of fruit puree, chocolate, oil seeds, coconut and rice milk, cane sugar, or maltitol. Then, this is mixed, pureed, and ready to go into the molds, after which the wooden sticks are added.

It takes about 20 minutes for the ice cream to freeze—then it’s dipped in a tub of warm water, which causes the mold to release. It is then pulled out and lined up using another machine, wrapped in a degradable PLA film, and put in a paper box. Some flavors are double layered or filled, in which case the molding-freezing process is repeated. They freeze 412 pieces at a time and can produce around 1,000 pieces per hour. Although most of the stages are supported by machines, it does require human labor—it’s heart-warming to witness the enthusiasm and dedication driving the team. And it’s particularly nice that Joe and his partner, Barbi Alföldi, who also works for the brand, spend so much time here that they decided to move their home right above the factory.

“What’s next? We don’t know yet. One thing is for sure: we wanted to build something, and in the meantime, we fell in love with it. Now we have a responsibility, for ourselves and the team. We’ll hold on as long as we can.”

And what’s an Anjuna ice pop like? It’s colorful, fruity, or sometimes chocolaty, made with oily seeds, but most of all, it tastes amazingly pure. There are so many varieties to choose from, from chocolate hazelnut to Joe’s favorite pistachio to Barbi’s pecan-vanilla version. The super-fruity raspberry-lime or the morello cherry-vanilla, and the classic coconut co-exist in complete harmony, but new flavors are constantly being experimented with. What’s more, you can ask for a vegan chocolate dip and topping in their dedicated shops, but you can also opt for an acai bowl with Viblance granola. And there’s never a shortage of plans: they’re currently working on opening up to the export market, as well as new products that can be enjoyed even in the winter. Because we always need something that makes the sun shine.

Anjuna | Web | Facebook | Instagram

Photos: Dániel Gaál

NASA space probe crashes into asteroid

The woman built from fragments—Orshi Drozdik’s exhibition in Budapest