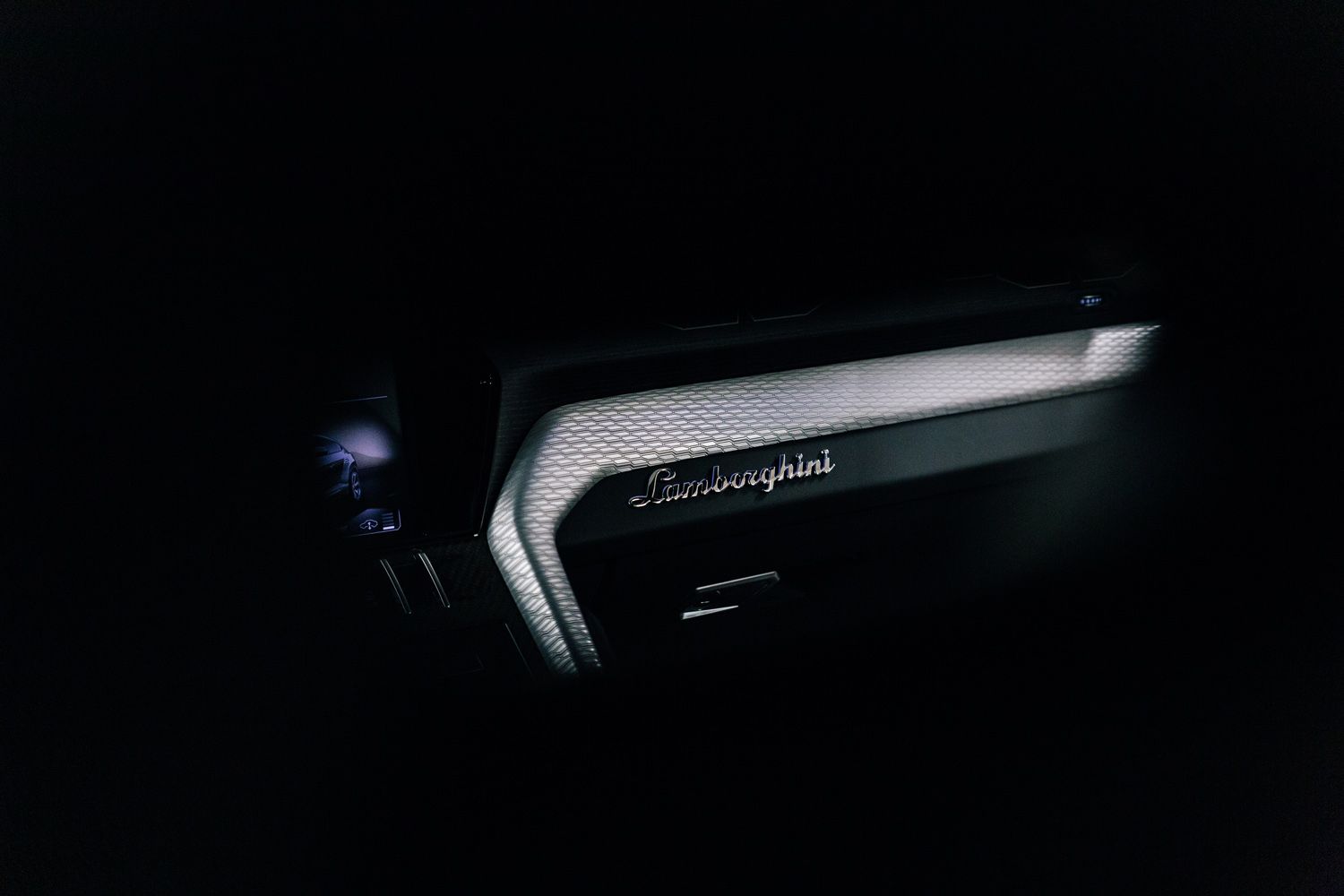

Aston Martin, BMW, Jaguar Land Rover, Mercedes-Benz, Lamborghini, Porsche and many more. But what do they all have in common? Apart from being premium car brands, at first glance, you might not think that they are all connected to a company operating in Hungary. MONO Group in Ipolytölgyes has been manufacturing professional automotive interior decoration elements for three decades. Olivier Wathieu, the company’s Sales and Project Director, answered our questions. Interview!

The story of MONO began in the eighties with cabinet maker Francois Bandura. Besides beautifully crafted materials and shapes, Francois has always been driven by his passion for technology and the automotive industry. He dreamed big and established MONO in Belgium in 1986, followed by a subsidiary in Hungary in 1989, which eventually became the company’s headquarters. He started alone but has now built a team of over a thousand experts, counting fourteen nationalities. His dream became reality and since then, MONO has been designing and manufacturing premium automotive interior decor elements: not considered as a supplier but rather recognized as an innovative and reliable partner by its customers.

The automotive industry is increasingly focusing on sustainability and sustainable development is at the heart of MONO’s business policy: how exactly is this kind of commitment reflected in the company’s activities?

Sustainability is indeed not only a wish but a commitment. It is not easy to implement measures and at the same time meet all the technical specifications of the automotive industry. For instance, you can use water-based paints, but their resistance is sometimes lower than that of solvent-based products. In practice, all parties have to play their part in the game: the raw material supplier, the car manufacturer and the user, and compromises should be made where possible.

One of our most important activities is research into the use of recycled plastic granules, which is a significant challenge. You need to control the supply chain: will there be enough plastic to be recycled with the right property? You need to control the behavior during injection: what percentage can be used mixed with new plastic granules and keep the same technical specifications? How does it behave in tests? Does it meet the specifications, or is it less resistant? If so, to what extent?

Mono has already been ISO 14000 certified for many years, so environmental protection is part of our DNA. For instance, we were the first decorative (trim) supplier on the market to use FSC certified timber. We have also started the development of sustainable veneers. We have developed a special process to be able to cut veneers from fruit trees. For fruit trees, it is important to know that when they no longer bear enough fruit, they are cut down and replaced by new ones: so we proposed to use these trees and give them a second life.

One big step for the company relates to the energy we consume. The aim is to cover a field with enough photovoltaic panels to generate our own electricity and make ourselves independent of external sources of energy—again, a big challenge. We also need power when our factories are manufacturing parts at night, which means that we need to install a solid battery system to store up the surplus energy we produce during the day.

Your clients include British, German and Italian brands, each with its own character and style. What are the general trends for premium car interiors these days in terms of materials, design and colors?

Indeed, every car manufacturer has its own identity. But the automotive world is global, and so are color and material trends. What we see is that car manufacturers are moving towards very bright colors. Furthermore, high-gloss finishes dominate over open-pore finishes. The combination of all these factors results in a very natural product. We work in the luxury sector; so real materials are essential.

The pandemic has transformed our lives in many areas. What exactly does this mean for the automotive industry: how will it transform it, and what changes and innovations can we expect?

To be honest, I don’t think that our products can influence the spread of the virus: it’s more about how responsible and responsive we are in protecting our employees, customers and suppliers. We made a swift decision to let people work from home as much as possible. We have equipped our computers with the latest video-conferencing apps, stopped all travel and worked to improve how we communicate with our customers and suppliers. Our rapid response has also been very effective: we now organize some visits, but we have definitely changed our mindset. We only meet when it is truly necessary.

Which of your assignments do you consider the most significant milestone in the company’s history?

Many collaborations have shaped our company: from the smallest to the biggest, each one has influenced us in some way, but I can’t really single one out. As we often say here: there’s more in two brains than in one. That is so true! When we collaborate, both parties start thinking of ideas that they had never thought of before and would have never thought of without meeting the other party. For me, the most impressive thing is the speed and the capacity to reflect and act from our COE/Owner, Francois Bandura. It gave wings to many initiatives, innovations that changed our business and made us stronger.

In addition to manufacturing, the MONO Group is also working to establish a research and development center. What activities and objectives will you focus on?

We have always had a development department; however, today, we devote much larger financial and human resources to it. We are working on several research topics, all of which are confidential because they relate to a specific project with a particular car manufacturer, so I can’t tell too much. Speaking more generally, I would highlight the printing process on aluminum, which we did not have in-house until now, as well as the anodization of the aluminum. We are also doing a lot of research into specific textiles, meshes, and special materials.

What is MONO Group focusing on now? What are your short and long-term goals?

Right now, we are very much focusing on the launching of the brand-new Range Rover. We are really proud to supply this car with a range of trims. Our long-term goal is to keep on innovating, for example, by using new material combinations and more recycled material. We are also taking an active role in the introduction of smart surfaces with backlit and capacitive switches. There is so much potential for innovation!

Body-and-heart warmer for winter hikes

Krakow takes up the fight against pandemic loneliness