Rotte Kft. was launched as a family business in 1996, and they managed to level up several times since then: today, they operate with five plants and have a turnover of 40 million Euros a year. Now, for a short period of time, industrial designer Sára Kele also joined the team of managers, engineers and manufacturers. In the framework of the design LAB program launched by the Hungarian Fashion and Design Agency—from the collaboration of a professional manufacturer and designer—a special furniture family was born. We talked to Katalin Gazdag, a project manager at Rotte Kft. and Sára Kele, the designer of the Tangens Office Home collection.

Katalin, could you please introduce Rotte Kft.’s activity to us?

Katalin Gazdag: The company group formed out of Rotte Kft. is an enterprise group that fulfills a leading role across the globe in the design and manufacturing of commercial equipment. We have communication and marketing experts, commerce specialists, architects, interior designers, industrial and graphic designers, engineers, masters and skilled workers working in our plants. The company, which is a fully Hungarian undertaking, was launched in 1991—the various production units of the company are still managed by family members, including, for example, the unit of Rotte Textil in Tata. Currently there is a capacity enhancement taking place here, and a new factory unit is also under construction, which will put to use today’s modern and automated manufacturing technologies. This plant manufactures the residential mattresses, beds, bed sets, smart beds and sofas available in retail sale entitled Rottex, Chamambra and Swiss-Tech. We have three stores in Tata, Komárom and Tatabánya, and we have also established partnerships with several large Hungarian corporations (Praktiker, Mömax, Auchan, Gigamatrac, Matrackirály).

Our assortment of products includes various mattresses—vacuum, foam, bio, classic, pocket spring, bonnell spring and kids’ mattresses—and toppers. We also offer ancillary textile products: towels, sheets, bathmats as well as bedclothes and bedlinen.

The year 2000 meant an important milestone for us: we opened up to the Romanian market, and production started in our timber and metal industry plants. In the latter, we work with our experienced engineers and with modern machinery, while the timber and textile plant contributes to the manufacturing of sofas, armchairs, tables and room dividers. In addition to Romania, we’ve also conquered other markets including Albania, Croatia, Bulgaria and the United Arab Emirates. We called to life our marketing department in 2014, and three years ago in 2018 we acquired the Swiss company Roge Swisstech, which allowed us to reach a new client layer.

Why did you consider it important to participate in the design LAB call announced by the HFDA?

Katalin Gazdag: The design LAB incubation program launched by the Hungarian Fashion and Design Agency offered a great opportunity for implementing the idea of applying to international and domestic tenders with our own office furniture collection which can be tailored to our partners’ needs instead of a randomly selected set. Additionally, it allowed us to create a product family of a quality that increases the reputation of the entire company. We have never worked with a designer in the case of a product intended for series production before, and in hindsight I can say that we should have done it much sooner. We are lucky to have worked with Sári, we complement each other very well in the work.

Sári, this is not your first time in the design LAB program. In a previous “semester”, you collaborated with the team of LumoConcept, where you tried your hand at lamp design. This time, in your collab with Rotte Kft., you’ve once again returned to furniture design. What happened in these six months?

Sári Kele: Rotte Kft. and I met at the Speed Dating event organized in the framework of the design LAB program. Kata and I shared very similar ideas, so much so that we were able to apply to the tender with a well-thought-out joint plan. The furniture design I outlined focused exactly on the sector Rotte set out to conquer—office furniture—and on top, the tools needed for its manufacturing (pipe bender, pipe laser) were only recently acquired by Rotte. They were also very open about the sustainability criteria.

The metal, timber and textile plants all participated in the manufacturing of the furniture—I could work with a lot of experts. The closest relationship was formed with the metal plant over the first months: with the product design engineer we optimized the nodes and frames to the pipe benders and lasers. In parallel, we were trying to find fabrics checking out both in terms of price and sustainability out of the products of lots of fabric manufacturers. We tested the seating surfaces in the textile plant. Quality, durability and long-term design were key factors during manufacturing, while the ability to be disassembled to parts was important during design for facilitating future repairs.

The “Tangens Office Home”, as also given away by the name, reflects both on comfortable home work and coziness in the workplace at the same time. It is an absolute hot topic amidst the current changed living circumstances. What’s the furniture collection’s super power?

Sári Kele: Luckily we receive positive feedback. In addition to practicability, we also managed to speak to people’s heart: customizability, the harmony of colors and materials and the choice of high quality materials also contributed to this greatly. Regarding the current situation, what motivated me was to pay attention to the importance of human connections: the metaphor of embracing also appears on the objects themselves, as the hard structure wraps around the delicate materials.

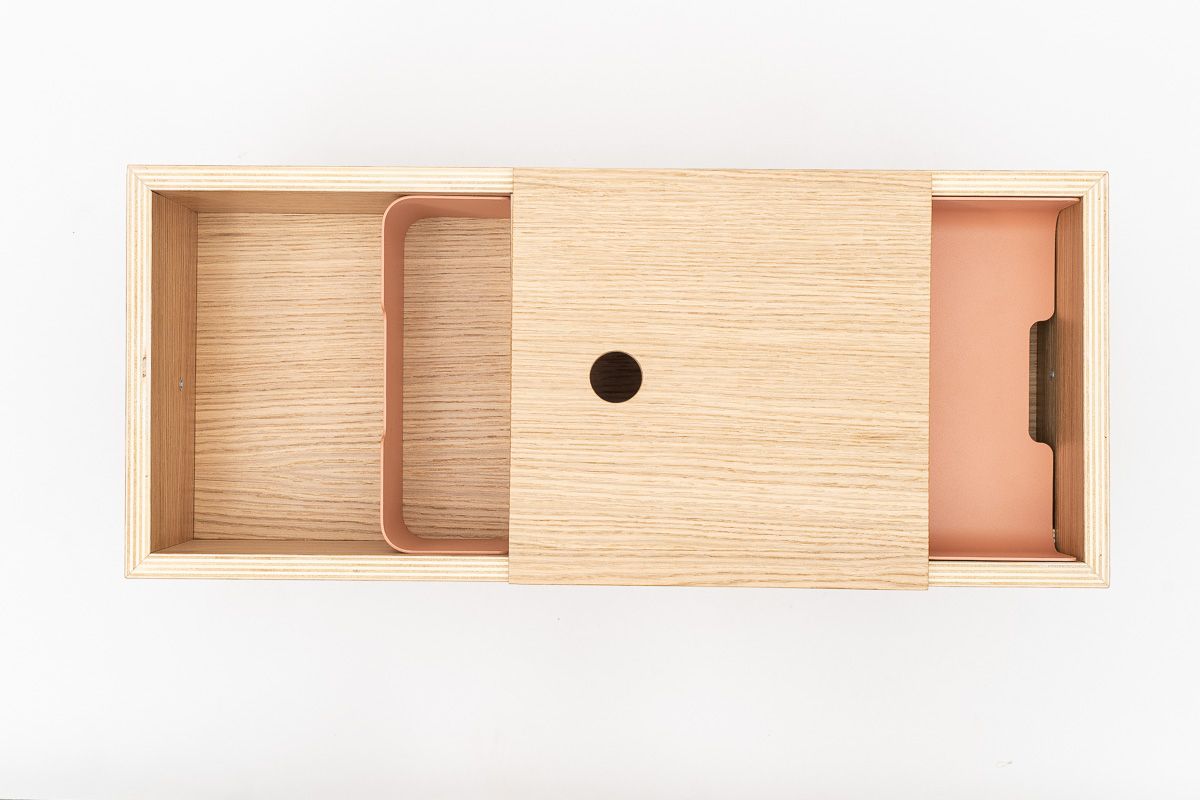

The establishment of agile office spaces is an absolute relevant topic: with its modularity, the Tangens reflects well on that. The furniture items can be shaped well to various builds in themselves already, and they fit into each other in a manner allowing the user to create various spatial arrangements in an instant. This is often necessary in today’s office life, in the case of team work. Working in an office usually equals sedentary work, this is why the Tangens focuses on this area exactly. The hard seating surfaces are built on a wave spring wooden frame structure, where the slightly elevated seating level of the furniture facilitates concentration. Subtleties like the ability to turn the container into a magazine rack or a flower holder also make its use loveable.

What was the biggest challenge in the course of the furniture family’s development from the side of the designer and the manufacturer?

Sári Kele: It might sound surprising, but we were able to tackle the challenges brought about by the epidemic quite well. There were, of course, some interruptions, unexpected hiatuses, for example when we waited several weeks for screws, or when the time of timber procurement was prolonged with several weeks compared to the usual—we also had to adjust to the changes occurring in the market.

Luckily with the helpful team we always managed to find a solution, may it be outdoor testing or video calls. Due to the new habits established over the past year, many people are more open to keep in contact online occasionally, but there were also participants from factories who hadn’t been forced to do so before. Already when Rotte and I first got acquainted, I was abroad and we could only meet in person months later.

From a designer’s side, the whole process was fruitful. Ensuring the stability of the thin tubular frame, in addition to aesthetic, was an important area of development: we dived deep into material research. I am happy that we were able to use recycled and natural materials in several places both in terms of upholstery fabrics and fillings. Rotte’s plant is absolutely well-equipped: powder coating, for instance, is carried out by automated lines that circulate the surplus back.

Let’s talk a bit about the furniture family’s life after production. The program announced by the agency is over: what plans do you have for the future with the collection? Are you perhaps thinking about developing a new product family?

Katalin Gazdag: We are working on launching the product on the market and on the first steps of sales. With Sári’s help, we’d love to submit the furniture to several design awards, too.

Sári Kele: In the fall we’re going to debut the furniture family at trade fairs, but we are already receiving inquiries from both domestic and international fields, from a commercial side, thanks to Rotte’s partner contacts. We’d love to continue working together. We have plans for developing the furniture family, and to design outdoor seating furniture, too. In the course of designing the Tangens, during the material research phase, we started looking for solutions to eliminate polyurethane sponge—this could be a huge step in the field of the sustainability of upholstered furniture.

Photos: Milán Rácmolnár

A Brutalist bus station was renewed in Brno | CHYBIK + KRISTOF

An iconic Hungarian board game comes to life on tees | DAIGE