Tomato soup with alphabet pasta getting cold, schnitzel with sticky rice and peas, the faded and soaked-out pieces of canned cherry, floating in a pink, sugary juice on the plate. The small plate, similarly to the portion plates used for serving soup and the main course, is made of snow-white porcelain, with a cobalt streak on the brim round and round, while the typical lukewarm tea of irreproducible taste awaits in the high porcelain jug to be filled into the cups of students.

Probably many Hungarians have similar memories about the school canteen, where the fragments of taste and scent are put in a frame by the silhouettes of the physical environment: tables, chairs, tablecloths, trays, cutlery, paper napkins and plates. For me, plates stand out in these memories: even today, when I eat somewhere new and I see an unknown shape, even though I know it’s not good manners, I still flip the plate to see the name of the factory at the back of the plate. There’s no point in denying it: this is a true object fetish.

Written by Piroska Novák

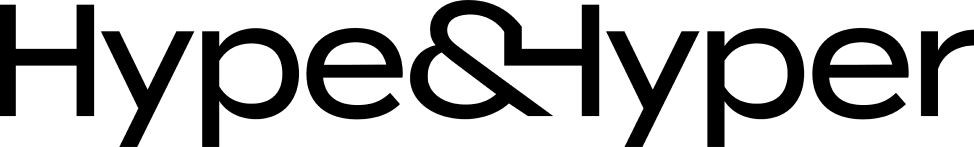

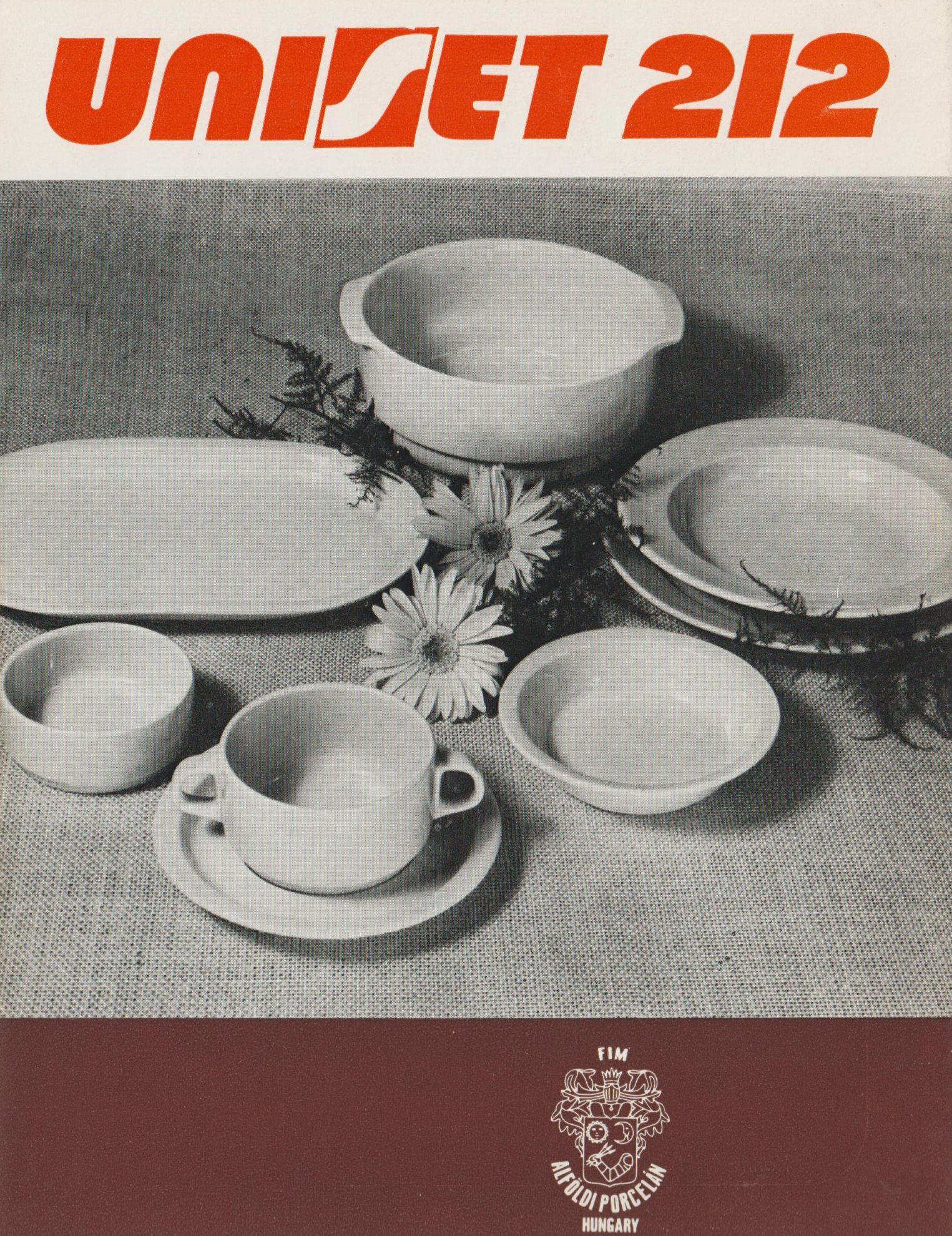

After a prolonged pause, we continue our Object Fetish series, which, according to our plans, will be published every two months. We will dedicate our big comeback to a porcelain tableware met and used by several generations in institutional catering, in cutaways of gastronomy or cooking shows, as well as on the increasingly popular social media platforms collecting and distributing retro objects. The UNISET-212 commercial tableware dominated Hungarian object culture as the “canteen set” for long decades, its pieces surface as unknown friends in the memories many of us have about institutional catering, yet the name of their designer, similarly to many others, fades into oblivion, and it didn’t get the spot it rightfully deserves in the history of Hungarian design.

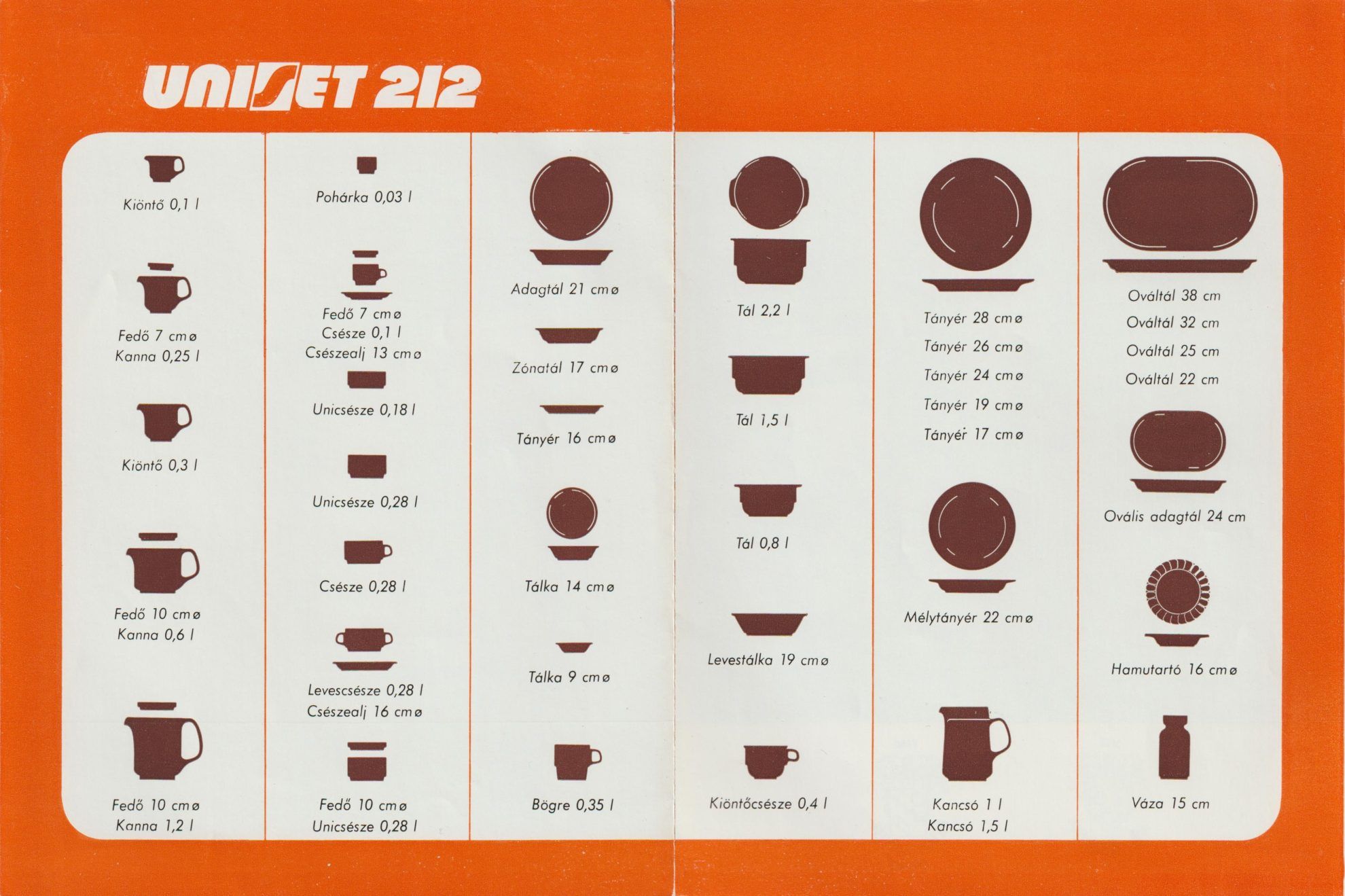

The UNISET-212 tableware: facts and numbers

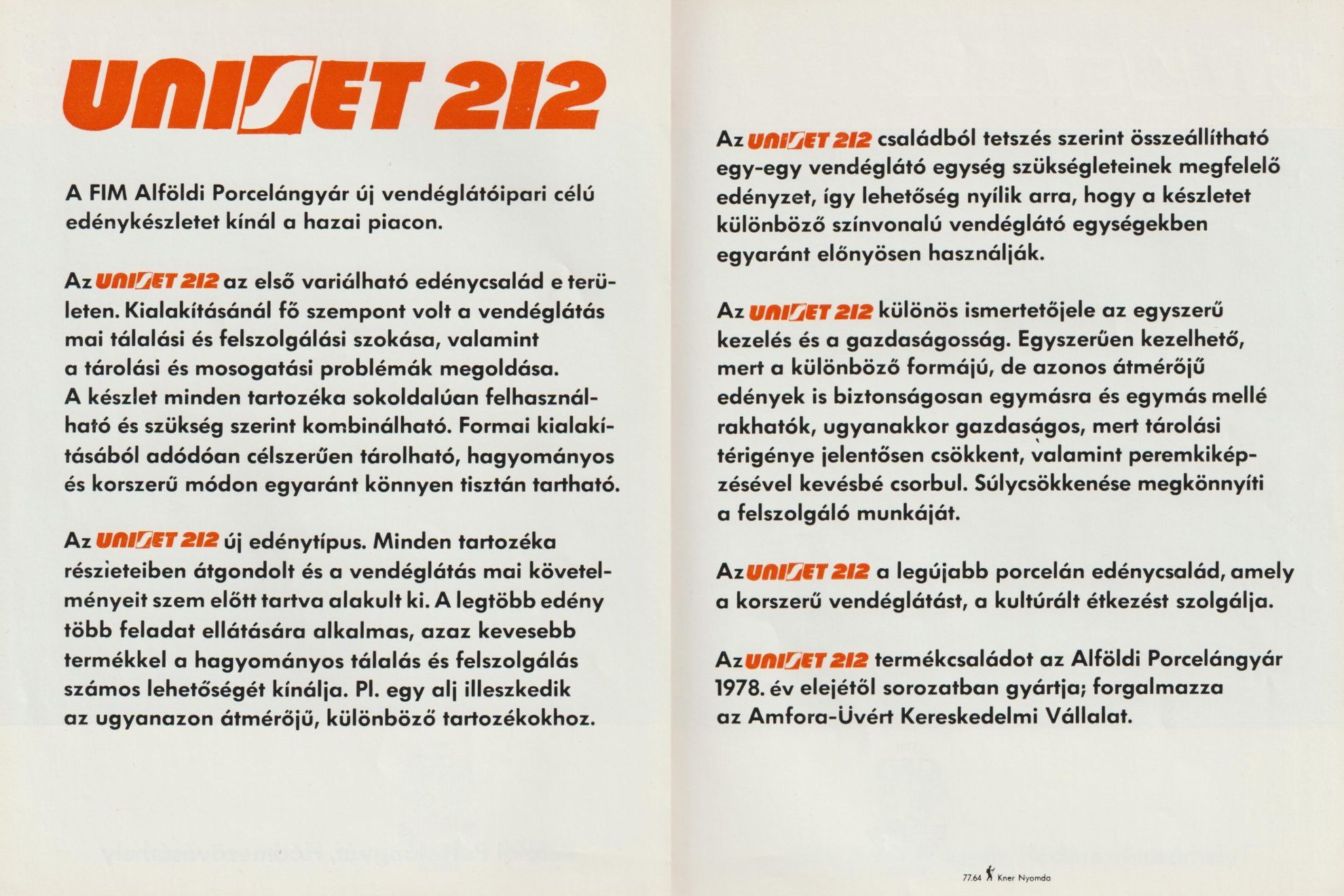

The UNISET-212 commercial tableware set was designed by Éva Ambrus, a designer of the Alföld Porcelain Factory in Hódmezővásárhely in 1976-1977, and was placed on the market in the subsequent year, in 1978. ‘Distribution’ may be a too simple and meaningless term, because it does not reflect the way public institutions were flooded with the items of the tableware set. It was designed primarily for catering units and customized to their needs, but the UNISET-212 set was also used in schools, hospitals, factory canteens and many households, too. From the second half of the 1980s, hotels could order the sets under the name “hotel porcelain,” decorated with their own names and logos. One of the fun facts in the history of the UNISET-212 is that although the factory was privatized after the regime change, and finally was sold to French Guy Degrenne S.A. in 1999, the pieces of the set can still be found in the product palette of the factory even after almost 45 years, unchanged in form. Why is the UNISET-212 set so timeless? What could be the secret of the peculiarity and success of Éva Ambrus’ design? Why can we meet and consume our meals from the pieces of the set even today?

The UNISET-212 set and what’s behind it

As we already revealed it before, the set was produced in Hódmezővásárhely in the Alföld Porcelain Factory – in the dish production unit of the same, to be more accurate. The Alföld Porcelain Factory was founded in 1965 in Hódmezővásárhely, in a city where even though ceramics trade had great traditions, they didn’t have experience or well-skilled labor force in the field of porcelain manufacture. The first plant of the Alföld Porcelain Factory complex embracing four silicates industry fields was the sanitary ceramics plant, handed over in 1967. It was followed by the plant of refractory materials and tools in 1968, and a year later, by the dish factory in 1969. Finally, the tile and floor panel manufacturing department started off in 1971. The dish factory was equipped with a modern semi-automatic production line imported from the German Democratic Republic, on which the once again imported Liana set was produced, primarily to fulfil the prescribed 3000 ton/year production quota. In addition to the Liana set manufactured in the GDR in large-scale series production, they also put the Krisztina-202 (Centrum Varia) tableware set designed by Istvánné Torma into production, and the joint design of potter János Mónus and plaster model creator Sándor Ceglédi employed by the factory: a commercial tableware set. The latter was characterized by folk ceramics art, and so it didn’t really meet the requirements of large-scale production.

A quality change in the selection of the dishware plant was brought by the Varia dishware design tender in 1972, which was announced jointly by the Ministry of Culture, the Industrial Design Council and Finomkerámiaipari Művek (Fine Ceramics Works, FIM) (1). In the tender announced in several categories, entrants had to design tableware sets suitable for mass production, with items available for purchasing on an item-by-item basis, so they can be “varied” with customers’ existing dishes. Another requirement was for the designs to be compatible with the large-scale industrial, mechanized and semi-automatized production conditions of the Alföld Porcelain Factory. The evaluation committee awarded the first prize to the Éva Ambrus’ set “Bella” in the category of complete tableware, which was marketed under the name Bella-207 from 1975. The set is built up of extremely clean, yet organic, almost sculpture-like classic and timeless forms, thus resolving the rigidity of industrial production, even though their designer opted for the round, incurving design because it was the best way to avoid the deformation of the material during firing. The Bella-207 set harmonizing design and technical aspects proved to be very successful and popular both in Hungary and abroad, especially in Italy.

The Bella-207 set enjoys a revival in popularity today: the diverse objects available with decorations of different aesthetic quality are primarily popular amongst the fans and collectors of retro items. The counterpoint of the porcelains decorated with patterns and offering the somewhat false feeling of a broad variety to consumers is the Alföld Porcelain Factory collection in the Ceramics and Glass Collection of the Museum of Applied Arts. The sets added into the museum’s inventory are sample pieces, and so-called white goods with a few exceptions, allowing us to examine the form of the objects, as there are no graphical elements on them that would distract our attention from the silhouettes.

The design theory behind the UNISET-212

The subject of our research, the UNISET-212 set was made for the value engineering competition announced by the National Technical Development Committee, as the work of the “value engineering team” consisting of the designer as well as the technical, economic and commercial experts. The designer, Éva Ambrus, summarized the very complex process of designing the UNISET-212 set in a case study, allowing us to learn every little detail. (2)

The design process started in 1976 with data collection and assessment of needs, for which the faculty of market research and market organization of Marx Károly University of Economics developed a survey, which was then delivered to catering units in Budapest and several cities in the country. “The informative material developed by the faculty covered the form, size, decoration of products, the requirements of storage and cleaning and the examination of opportunities procurement, and was concluded with a recommendation for market organization developed based on the findings.” (3)

After assessing the received answers and consumer needs, they developed the design principles of each item with the method of function analysis, which contributed to the systemization of the requirements of multi-functional use greatly. They recorded these aspects on target-setting sheets. “We aimed to create a complete set consisting of the least possible items and suitable for fulfilling all the functions that can rationally be implemented with porcelainware. Taking all this into consideration, the criteria pertaining to the design of the set including all functional and aesthetics elements were established.” (4)

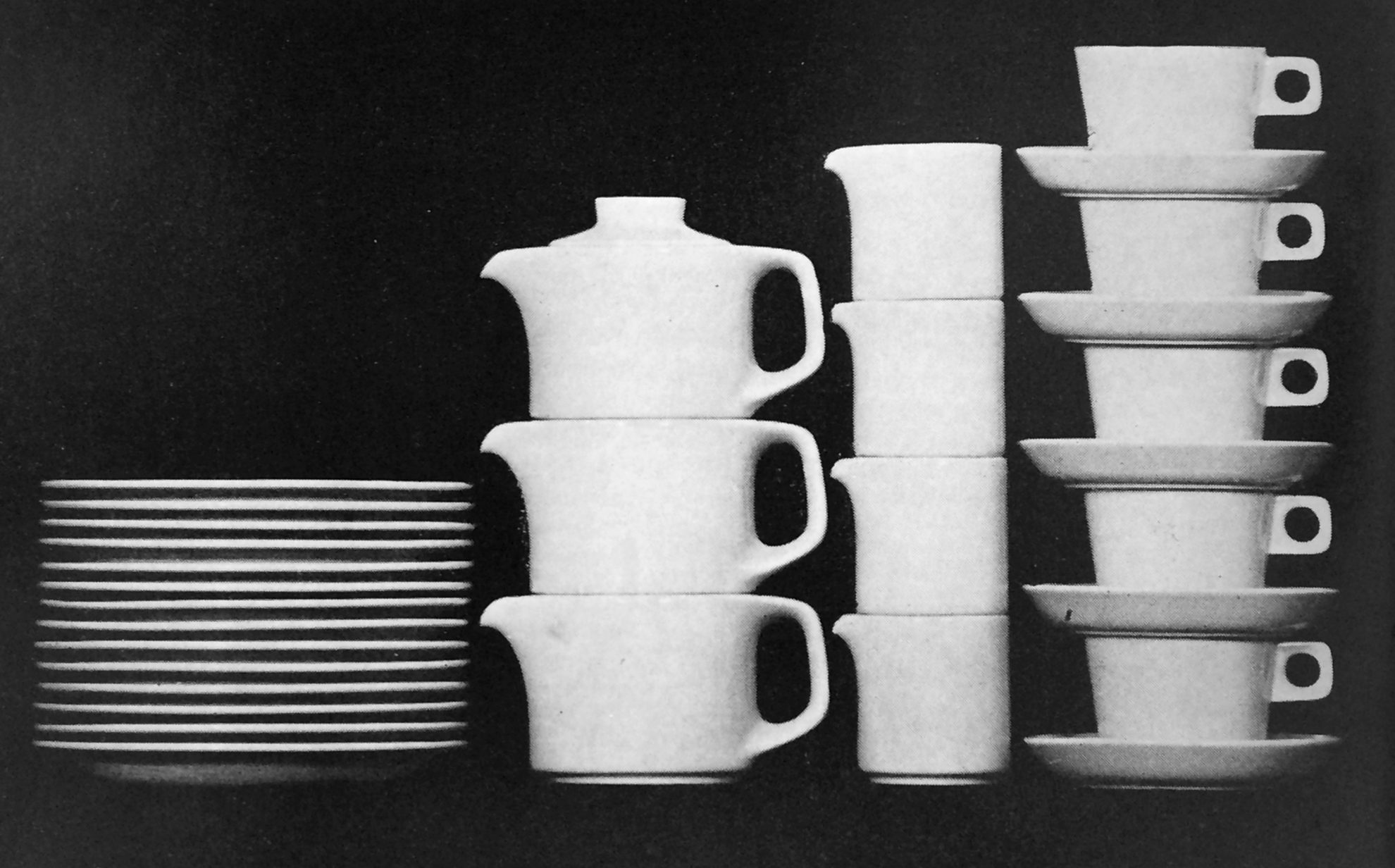

The method of value engineering itself meant that they designed and precisely calculated the production conditions of the cost-effective manufacturing of each and every object related to the set. Éva Ambrus developed the ratio system and the basic forms of the set based on the aspects recorded on the target-setting sheets in the case of the tea, coffee and tableware set, too, which were then evaluated by the designer collective jointly. This is how the module system and the basic concept applied when designing the product set were finalized: „[…] a fundamentally cylindric form and its division by the functionally adjusting surfaces. To resolve the somewhat mechanic nature resulting from the cylindrical basic form, I rounded the edges and surfaces that do not have a functional role in fitting, and I also chose more arched and rounded solutions for shaping the handles and spout openings connected to the basic body.” (5)

The production of the prototype was preceded by a meeting with and evaluation involving the leaders of the factory as well as the representatives of the hospitality industry and trade. Éva Ambrus considered the results of the meeting and the evaluation useful and educational, which were all incorporated into the final tasks of development and production, as well as into the organization of introduction to the market. The UNISET-212 commercial set was placed on the market in 1978, and its advertisements, foldouts, product catalogue and packaging was designed by graphic designer Mária Zahorán.

The UNISET-212 set is a fine and illustrative example of systematic design (6). The items of the dish set can be combined with each other well, they are suitable to fulfil several functions, and can be placed inside each other safely (they are stackable), thus facilitating storage, carriage, as well as setting and clearing the table. At the points of the objects ensuring ergonomic use that are more vulnerable and more exposed to increased use (for example, the rims and spouts), the material is thicker, thus reducing the risk of chipping and breaking resulting from use. The UNISET-212 created with the method of value engineering and the practical application of a complex designer approach proved to be extremely successful, was a dominant player of the hospitality sector and institutional catering, and it was frequently used at home, on family tables, too. Its unbroken success is also represented by the fact that Alföldi Edénygyár Zrt. (the dish production unit of the former Alföld Porcelain Factory), owned by the French Guy Degrenne S.A. from 1999 still distributes the pieces of the UNISET-212 set even today, because there is still demand for it on the market.

The key(s) to success

The success of the UNISET-212 is the result of the favorable constellation of several factors. On the one hand, the consumers of the era “had a thirst” for well-designed objects aligned with the environment, that they could not only use in their workplace or in public institutions, but which they could also purchase for their homes. In József Vadas’ volume titled “A forma tartalma” (The content of the form), one can read about many of these requirements, and one can also learn about the ordeals of an everyday lunch. “People get hungry while taking a walk. It’s time to enter a restaurant. It will be edifying, since Hungarian restaurants are like stages. One enters the room, however, he is not welcomed by a space confined by floor, ceiling and walls, but the flurry of beams and other wooden structures, almost like a theater stage, many times with Hungarian decorations and plates on the wall. This atmosphere is greatly ruined if one has to wait for the food and if the food is cold. We couldn’t try it, we didn’t get a table. A self-service restaurant will be faster, one thinks. We are walking on the avenue, one café follows another, but no self-service restaurants on the horizon. Yet design should start somewhere here, by exploring how many people eat or at least would like to eat their lunch amongst humane circumstances […] Finally, we have arrived. We can see the place in advance, because the line is so long; it starts on the street. Standing in queues is boring? Well, it’s also entertaining. You can watch those already eating; you can see how five people are crowded to a single table, which is only comfortable for two (you can try it out in the evening). You can also entertain yourself with the magic tricks how a hungry guest places the plates that cannot be stacked on top of each other on a tray of an ungainly form. You don’t even need a menu: you choose from the plates of others. It all starts to become really painful when it’s finally your turn, and you try to find a place to sit with your tray stacked up full. You sit on the chair, but you soon find it that you cannot pull it under yourself: it has a wide base. So you have to sit on the edge, that is, in an uncomfortable position. But this discomfort seems to be bearable compared to the disgusting aluminum cutlery. And there’s no use complaining. A native in the capital knows what the answer will be: please, they even steal these, just imagine if we put out nickel silver cutlery. […]

The recent case of the knife and the fork […] offers more conclusions than just the nickel silver cutlery being appetizing and the aluminum being disgusting. It means that either there are no designer applied artists in the hospitality industry, or if there are, they cannot enforce the principle that the furnishing activity must start from the requirements of use.” (7)

In the case of the UNISET-212 set, the consumer needs, the intentions and potential of the designer luckily met the will of central control, this resulted in the announcement of the tender, in the framework of which the management of Fine Ceramics Works and the Alföld Porcelain Factory allowed the holistic designer approach encompassing all details to prevail. A direct and justified antecedent of this approach was the experiment of the Kitchen Program for Prefabricated Houses conducted between 1972 and 1975. (8) The line of factories participating in the Kitchen Program for Prefabricated Houses included the Alföld Porcelain Factory, amongst others, the designer collective of which was led by Éva Ambrus. The House Factory set of dishes designed by her was completed in 1974-1975, a prototype was produced of it, which was presented at the Budapest International Fair (BNV) in the fall of 1975, the large-scale exhibition showcasing the results of the program (almost 400 objects). The set included a tea and coffee set as well as tableware, reducing the number of the pieces fulfilling the various functions to the minimum. The forms were rounded, yet still stackable, thus saving space in the cupboard for the other utensils. In spite of the massive work done and the promising developments, unfortunately, the Kitchen Program for Prefabricated Houses remained an experiment; a small ratio of the prototypes created were put into mass production, however, the design program developed had a long-lasting and beneficial impact on the training of designers and the approach pursued by factory designers.

The method of value engineering applied in the course of designing the UNISET-212 set, that is, the preliminary assessment of the costs of every item of the set from the perspective of production and distribution should also be mentioned amongst the factors bringing success, and it deserves a prominent place. Éva Ambrus could acquire the basics of value engineering and systematic design at the Hungarian College of Applied Arts, at the classes of Dr. József Hegedűs (9), which knowledge she could further deepen and utilize in her work in practice as a designer.

Another component of long-term popularity and success on the market is the fact that through the decals ornamenting the objects, the given restaurants and hotels could use the set with their own emblem or a custom-designed pattern, and the factory was able to replace the pieces continuously. Therefore, the samples put on the market did not only ensure a wide selection, but they also promoted the establishment of brand culture and corporate identity.

The systematic, space-saving and stackable design of the UNISET-212 commercial set fully complied with the requirements of the era. One could even say “it was in the air.” Similar porcelain sets were put on the market on the continent, however, Éva Ambrus had little chance to learn about them. An earlier example is the Kilta set designed by Kaj Franck, launched by the Finnish Arabia porcelain factory in 1952. Franck redesigned the set available for purchasing item by item, with a clean design and covered only in colorful glaze as decoration, serving the purpose of practical use in 1981, and it has been in production ever since under the name Teema, now under Iittala and Fiskars company group uniting Finnish brands.

Another Western European forerunner was the TC100 set of German Rosenthal porcelain concern’s brand Thomas, designed by Hans (Nick) Roericht as his diploma project in 1958-1959. The pieces of the set reflect functionalism, rational and precisely implemented German design as well as the principles of the Ulm School of Design, and so it is not a coincidence that the collection of MoMA in New York also preserves a few pieces. The System B1100 commercial service of Weiden-based Baushcer porcelain factory from 1959-1960 is another example from the western side of the iron curtain – its designer, Heinz. E. Engler designed several similar systematic plate families.

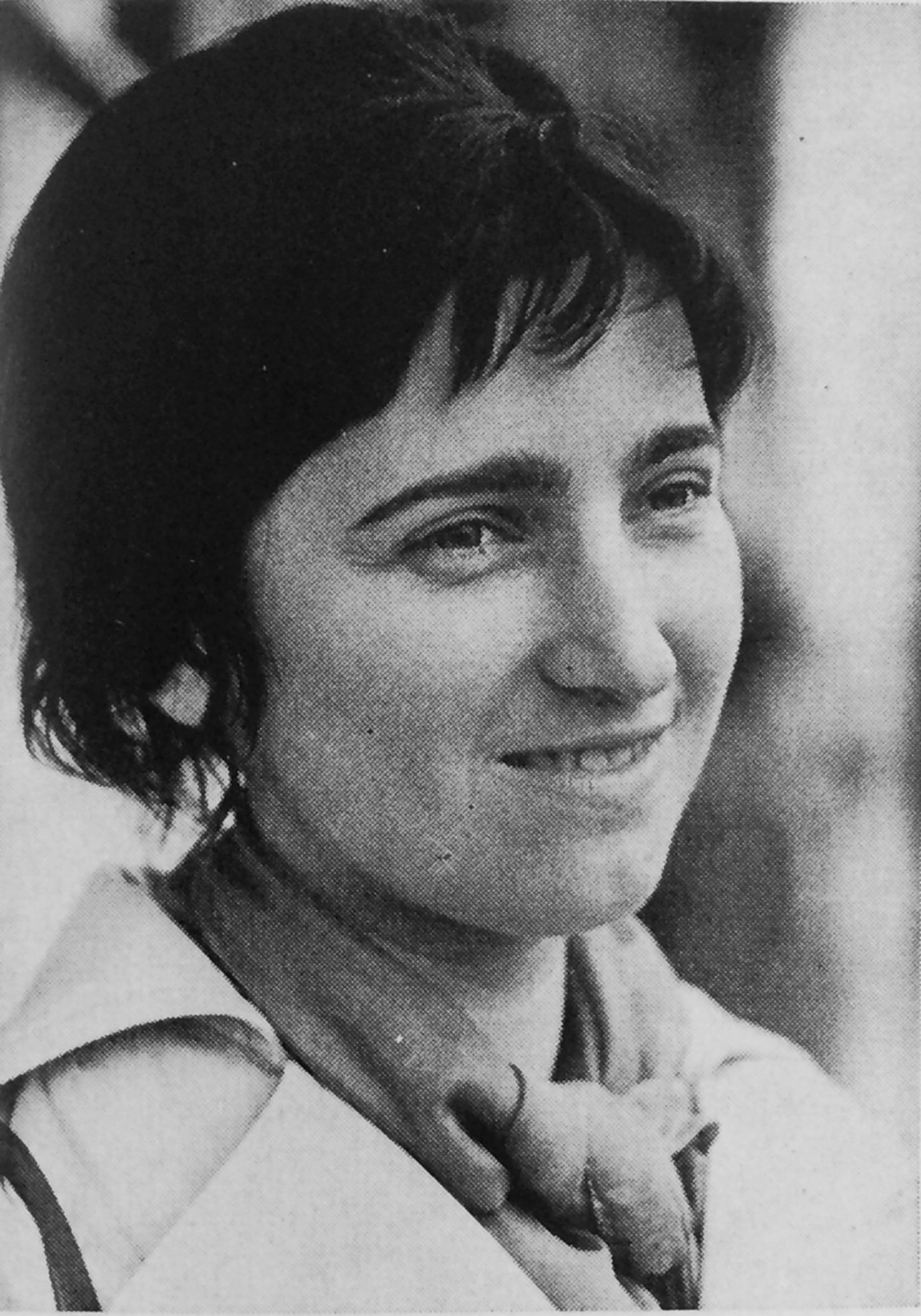

Another thing that all the aforementioned examples have in common is that their designers are all well-known, internationally acknowledged creators, and their referenced designs are still produced today. Iittala refers to Kaj Franck as a “designer icon” and “a hero of Finnish design” on its website, and Hans Roericht lies behind his completed work proudly, fully aware of his worth as a designer. However, sadly, we cannot say this about Éva Ambrus, her name is not known except in a small professional circle, even though she created something significant and lasting in Hungarian object culture with the UNISET-212, we cannot find another porcelain plate set of the kind.

The UNISET-212 set and the person behind it

Éva Ambrus studied at the department of porcelain design of the Hungarian College of Applied Arts between 1962 and 1967. She graduated in the first class where students were trained for large-scale, factory production and fulfilling the actual consumer needs of the era. Imre Schrammel, the head of the department supported industrial design in the training, while György Jánossy drew the students’ attention primarily to the connection points between architecture and ceramics in his lectures. The diploma projects of the legendary class graduating in 1967 consisted of a plate set (also) suitable for industrial production and a wall covering model comprising of elements. (10)

Éva Ambrus designed her tableware set for the Café of the Budapest Szálló (Körszálló) built at the time, and the application of the harmonious unity of usability, practicality and modern design can be observed already in this set. In light of the antecedents, it’s no surprise that Ambrus, a scholar of the Herendi Porcelain Factory at college, didn’t want to focus on worn-out traditions and re-designing the classic Herendi form and pattern treasure, but wanted to respond to the challenges of the era with her objects. Therefore, from 1967, she chose to work for FIM’s factory equipped with the most modern technology: Alföld Porcelain Factory in Hódmezővásárhely. Her initial years passed slowly in the factory, where the freshly graduated porcelain designer was welcomed with distrust (11), and so she was only assigned smaller tasks such as designing new patterns for existing products and designing and redesigning the maker’s mark of the Alföld Porcelain Factory – the latter was actually used for some years on the products manufactured in the factory. Most of the time the designer herself prepared the prototypes of her designs (many times created independently), but these were not placed into production.

The breakthrough was brought by the Varia dish designing tender in 1972 and the Bella-207 set, from then on, her career took off: she was promoted to art director from a porcelain designer. This upward period lasted approximately until 1980, when the Alföld Porcelain Factory started to take on jobs for foreign companies, which meant that factory manufactured finished designs, not requiring the work of Hungarian porcelain designers. Éva Ambrus found herself in a similar situation to the one she was in when she started working in the factory in 1967: being a designer in anonymity, with her designs being rejected. The uncertainty of the situation of factory designers was further aggravated by the cessation of Fine Ceramics Works in 1982.

Éva Ambrus left the Alföld Porcelain Factory in 1984, and became a freelance designer. Her two-month study trip to Finland back in 1979 meant a turning point for her: this was when she first encountered the designer status rich in acknowledgements and also appreciated by the society in addition to the representatives of the profession, which she never experienced in Hódmezővásárhely. The study trip affirmed her later decision from many perspectives.

The UNISET-212 and what comes after it

After 1984, Éva Ambrus mainly designed corporate and giftware, and sets of small item numbers. In addition, she got many enquiries, especially around the Millennium, to create public space ceramics fountains, in the design process of which she also used systematic forms variable from elements – it’s safe to say that she was also a successful and busy ceramist as a freelancer.

In the meantime, the UNISET-212 was continuously produced and used, the same as it is today. The formal solutions and the stackable design has attached to the furnishing of canteens so much that they also started to manufacture it from plastic. Although plastic is a lighter material that can be produced more cost-effectively than porcelain, however, it is much less resistant to surface scratches, and, therefore, its material gets worn out sooner, and so it must be replaced more frequently. Another disadvantage is that plastic cannot compete with porcelain’s cleanability. We can read about the history of the portion plates made of PET-G plastic at the REPETA® unbreakable serving pot set page of Hunnia Kristály Kft., at the same time, at some point they say that they did not wish to copy the design of the UNISET-212 slavishly, but the resemblance between the two is uncanny. Even more, the company does not only produce dishes resembling the designs of the UNISET-212 from plastic, but from porcelain, too. Although Alföld Porcelán Edénygyár Zrt. is mentioned in the description, the name of the designer is left out, the same way there is no way to know whether they used Éva Ambrus’ intellectual property in compliance with laws, and it’s also a question why they didn’t engage a designer for the task. An example from the (dark) side of market competition also points out how a tried-and-true, frequently seen and used, timeless shape can be interwoven into a nation’s and era’s object culture in an inseparable manner.

Although it’s a personal side note, I would still consider it relevant and worthy of mentioning that since I have been focusing on the work and career of Éva Ambrus, my friends also keep an open eye and keep rejoicing me with their revelations, which further support and substantiate the emblematic nature and popularity of the UNISET-212.

Notes, references:

(1) One of the turning points of the history of the Hungarian silicates industry was the nationalization in 1948-1949, and the foundation of the Finomkerámiaipari Országos Vállalat (Fine Ceramics National Company, FOV) in 1963, operating under the name Fine Ceramics Works (FIM) from 1968, controlling the operation and activities of eleven factories, determining their product profile and palette, the production and distribution structure, deciding in matters related to personnel, and, thus, about hiring designers, too. FIM controlled the following factories: Alföldi Porcelain Factory, Budapest Porcelain Factory, Gránit Grinding Disc and Stoneware Factory, Herendi Porcelain Factory, Hódmezővásárhelyi Majolica Factory, Hollóházi Porcelain Factory, Kalocsai Porcelain Painting Plant, Kőbányai Porcelain Factory, Romhányi Construction Ceramics Factory, Városlődi Majolica Factory, Zsolnay Porcelain Factory.

(2) AMBRUS Éva (1977): Az UNISET-212 vendéglátó-ipari edénycsalád kialakítása. Esettanulmány. (The Design of the UNISET-212 Commercial Tableware. Case Study.) In Ipari Forma.1977/5, 15-17.

(3) AMBRUS Éva (1977): 16.

(4) AMBRUS Éva (1977): 16.

(5) AMBRUS Éva (1977): 17.

(6) The concept of systematic design was made one of the principles of design methodology by American designer and theorist Jay Doblin at the end of the 1960s. The essence of the method is that it’s not the finished products that should point to a process or a system, but vice versa: the given process should define the line of optimized products designed for the function offering multiple uses. To learn more about systematic design in Hungarian language, see: DOBLIN, Jay (1981 [1971]): A design tudománya. (The Science of Design.) SZŐKE Tibor (transl.) In Design-Alapelvek. Válogatás az ipari forma irodalmából. (Design Principles. Selection from the Literature of Industrial Design.) ERNYEY Gyula (selecting and editing, and writing the transitions) Budapest: Hungarian Chamber of Commerce, Industrial Design Information Center – Design Center, 1981, 392-401. [Originally: DOBLIN, Jay (1971): A design tudománya. (The Science of Design.) The lecture manuscript of the Industrial Design symposium, Budapest: MTESZ (Műszaki és Természettudományi Egyesületek Szövetsége, Federation of Technical and Scientific Societies), 1-14.]

(7) VADAS József (1981): Ebédelünk. (Having lunch.) In A forma tartalma. Az ipari formatervezésről. (The Content of Form. About Industrial Design.) Budapest Kossuth Publishing House, 71-74

(8) The first systematic design experiment started in Hungary in December 1972, called to life with the aim of making the cramped kitchens of house factory type apartments built with the panel technology more livable, led by Sándor Borz Kováts, Mihály Pohárnok and György Soltész. The Kitchen Program for Prefabricated Houses approached the problem to be solved from a comprehensive, holistic perspective, and so it encompassed the work of experts of several disciplines. They measured the operation of house factory kitchens with sociological surveys and then analyzed them, and then they designed the work processes carried out in the kitchen, together with their space and object requirements, for which they created exact function templates, and they established relationships with the representatives of the relevant industries, so that the prototypes created as a result of their work could be placed into mass production and distribution.

(9) For more info, see:

HEGEDŰS József (1983): Értékelemzés és rendszerelmélet az ipari formatervezésben. (Value Engineering and Systematic Theory in Industrial Design.) Budapest Tankönyvkiadó.

HEGEDŰS József (1982): Az értékelemzés gyakorlati megvalósítása. (Practical Implementation of Value Engineering.) Budapest PRODINFORM.

HEGEDŰS József (1978): Értékelemzés az ipari formatervezésben. (Value Engineering in Industrial Design.) Budapest Tankönyvkiadó.

HEGEDŰS József (1975): Rendszerelmélet az ipari formatervezésben. (Systematic Theory in Industrial Design.) Budapest Tankönyvkiadó. [MIF Faculty of Industrial Design, manuscript.]

(10) Five students graduated from the department of porcelain design of the Hungarian College of Applied Arts in 1967: Éva Ambrus, Miklós Eőry, Erzsébet Láng, Károly Szekeres, Anikó W. Kálmán. For more info see: HAULISCH Lenke (1968): Porcelán ’67. (Porcelain ‘67.) In Magyar Építőművészet. 1968/1, 63-64.

(11) A typical symptom of designers graduating from the Hungarian College of Applied Arts, in addition to problems with integration at their workplace, was how misunderstood they were; József Vadas’ writing also provides a graphic description of this phenomenon: VADAS József (1981): Gyári tervezők. (Factory Designers.) In A forma tartalma. Az ipari formatervezésről. (The Content of Form. About Industrial Design.) Budapest Kossuth Publishing House, 82-85

In our Object Fetish article series, we introduce the emblematic pieces of Hungarian object culture. We go after objects and their designers: we ask questions, we investigate and we learn. A four-hand piece by design theorists Kitti Mayer and Piroska Novák, published every two months.

In partnership with:

An apartment converted into a park in a tower block

Online knowledge sharing (not only for creatives)