The office building on Bláthy Ottó Street and its surroundings are “the Mecca of Jewelers”—this is where the designers who launched their own jewelry brand make a pilgrimage: everything from gems to gift boxes is available here, and most of the work processes take place within these walls. Mortal people cannot, only and exclusively professionals can gain admission to this Paradise. We accompanied jewelry designer Fruzsi Fekete and looked at what happens to a piece of silver jewelry before it gets to its happy owner.

Above all, it is important to clarify: the jewelry designer does not work alone. They sit at the goldsmith’s table for long hours: soldering, polishing, sawing, grinding—designing and continuously shaping the object, but there are certain workflows that require a professional. Although Fruzsi Fekete also named her brand after herself, Fruzsi Fekete Jewelry would not be where it is today but for craftsmen who taught her the ins and outs of the profession on the one hand, and those who do their part every day in making a special FFJ piece.

Of course, the lion’s share of the work still belongs to the designer: in the case of Fruzsi, this is extremely true, because she shapes each piece of jewelry from beeswax one by one, and each piece acquires its final shape thanks to the lost-wax process (of which we talked about in one of our previous articles—the Ed.). But let’s see what happens to a piece of jewelry beyond the goldsmith’s table!

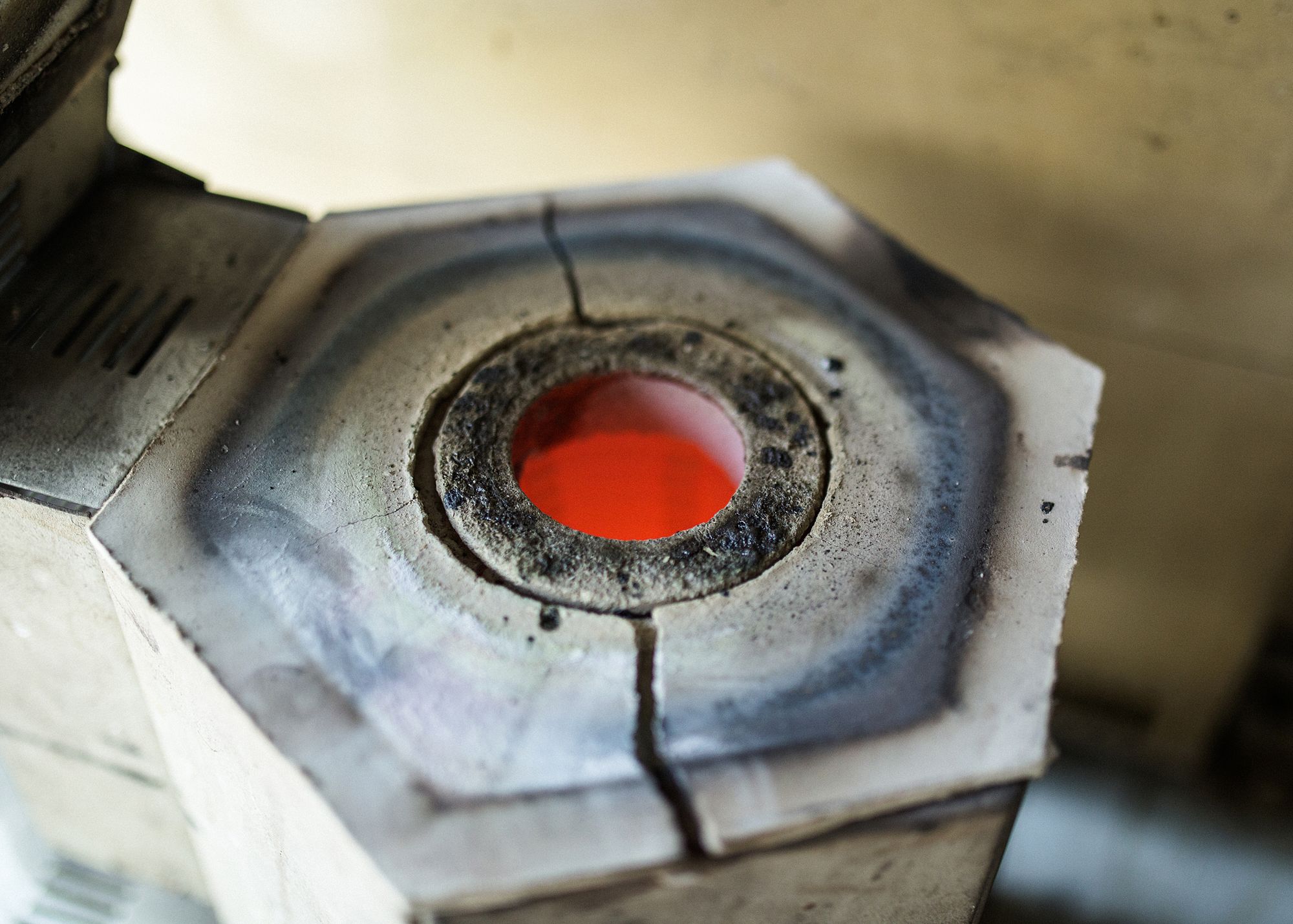

The shaping of the jewelry and the perfect “polishing” of the finished pieces takes place in Fruzsi’s workshop, the next phase, the metal casting, takes place in the neighborhood of Bláthy Ottó Street. Here we find Imre Kakas’ workshop (GoldRose Bt.), where the ovens glow every Tuesday and Thursday. The beeswax jewelry shaped by Fruzsi (along with several other pieces of jewelry) is placed on a frame-like structure, that is, “bouqueted”—this little bouquet was blue when we visited. Why, you ask?

In addition to beeswax, jewelry designers use other waxes: hard wax is usually dark blue, and there is also a wax in a turquoise hue. The latter is the injected wax used for reproduction. This is because many designers, unlike Fruzsi, do not shape their jewelry one by one, but create a so-called sample, the shape of which is preserved by a rubber negative. This negative can then be filled with wax countless more times—speeding up the process.

The put-together “bouquet” is most like an abstract statuette, which is then placed in a metal container and the whole thing is cast with gypsum. Once the gypsum is hardened, the structure is placed in the oven: the wax leaves its original place when exposed to heat, and the negative form remains afterwards—this is where the molten silver enters, filling the “gaps” and the raw casting is born.

So our silver casting is ready. What follows next? Fruzsi saws off the inlet nozzles left over from the bouquet in her home workshop and then shapes the jewel further: for example, a “Leaves” earring requires grinding and soldering, among other things.

So for a less complex piece of jewelry, the formula is to shape it from beeswax, mold it, and finally refine it. But what if a customer turns to Fruzsi with a request to make a ring that sparkles with a gemstone? Or want to see a motto, a year, a monogram in it? Or want gilded jewelry?

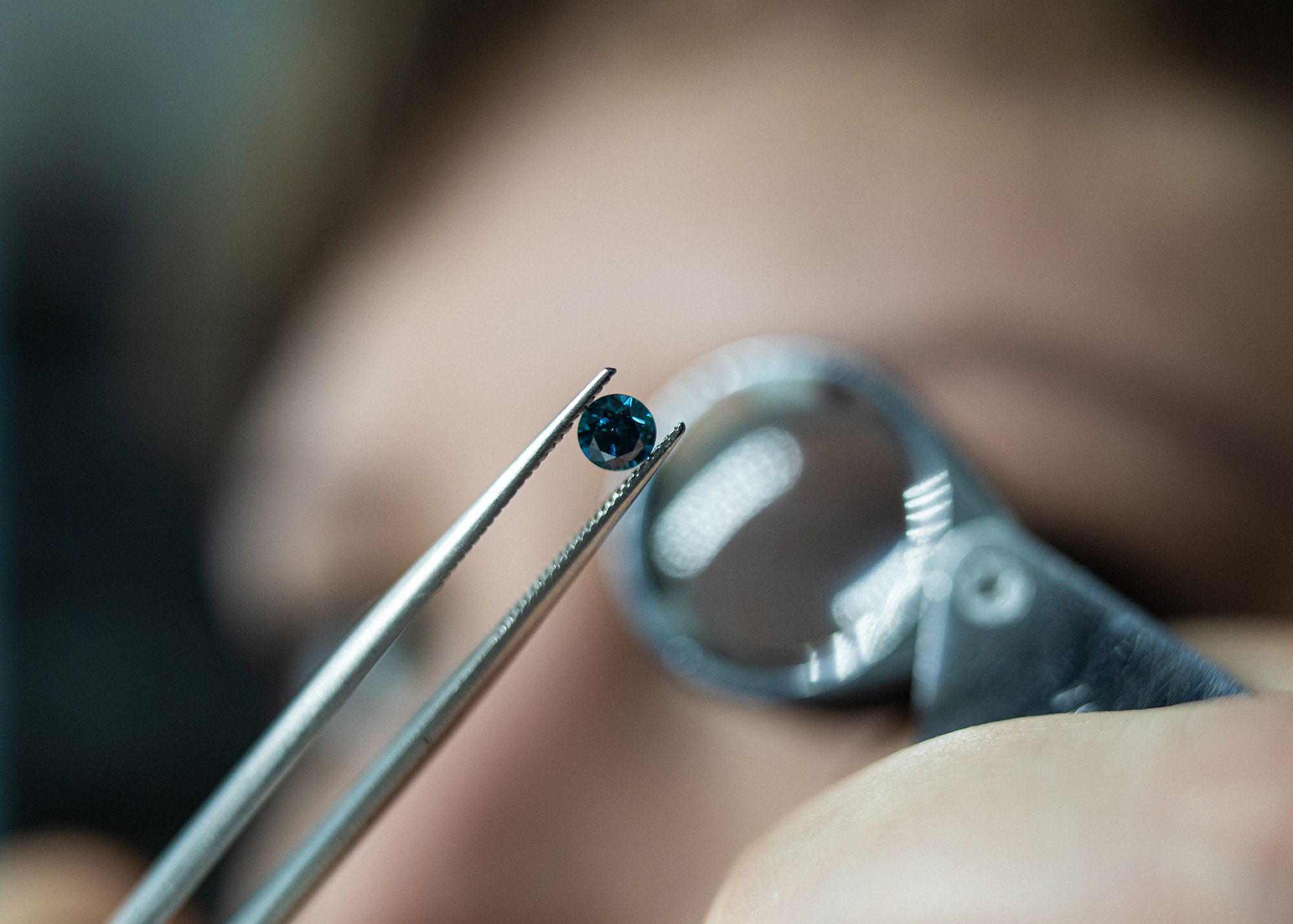

In “The Mecca of Jewelers,” we arrive at a screen door—inside the building, as it turns out, there are plenty of such doors, but these screens form a little diamond. Timi, the gem expert, is already waiting for us. We arrive in a tiny room, where various stones and minerals rest behind closed glass windows, the tiniest stones are waiting in small bags. A micrometer and tweezers on the table and a special sunlight lamp is needed to view the gems under proper lighting. The lupe, which can be pulled on the index finger, is essential for the latter operation, and of course the carat balance cannot be missing either.

Fruzsi’s favorites are black and blue diamonds and blue sapphires, and most of this jewelry features these stones. The tiny gems are almost barely visible to the naked eye: a bad move is enough and they are already rolling around. How valuable a gemstone is can be determined by the four properties of the stone: color, quality, polishing, and size. And while nature produces countless wonderful stones, various treatment procedures can also artificially change the color of a gemstone. This treasure mine is a kind of purchasing place: Fruzsi selects the coveted stone here, which is then sent to the stone setter.

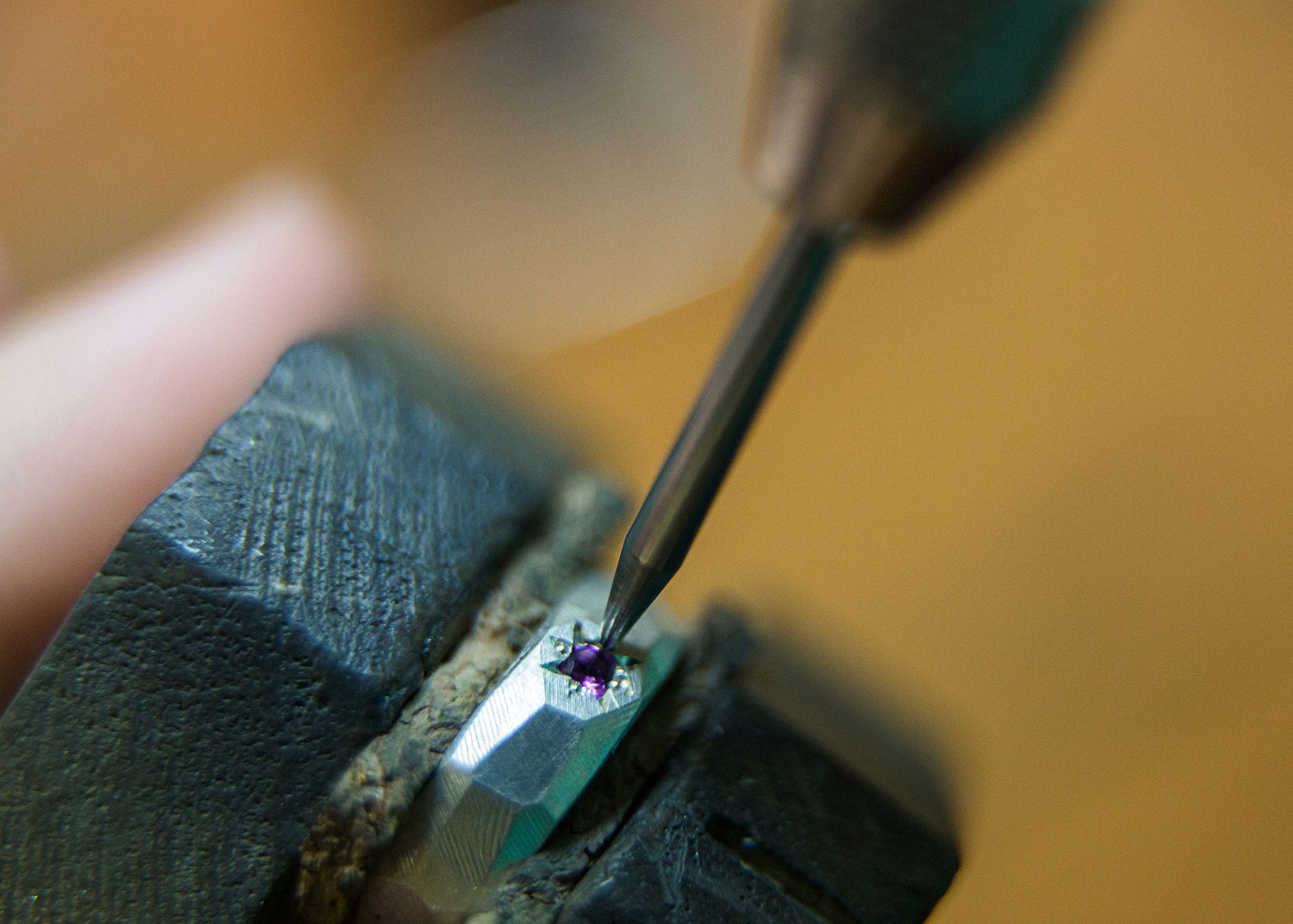

Melinda works in the next corridor in an even smaller room. The goldsmith’s table is full of tools, and in the middle is the six-kilo engraving ball. On the side is an apparatus similar to that of dentists, which is essential for Melinda’s work: this machine is used for drilling and milling metal jewelry. On the table, we notice a large, red inscription: “BLINK!”.

Melinda studied goldsmithing, her parents used to earn their living with it, and although it was suggested that she also learn to be an engraver, she eventually decided to be a stone setter. She learned the profession from an old craftsman, and she has been working as a stone setter since 2000, and in addition to Fruzsi she also collaborates with several other Hungarian designers.

Her work is precise and meticulous. She places the ring in the engraving ball, which actually functions as a vise: so that the jewelry is not damaged, the clamped ring is held in place by cork boards. Melinda first marks the place of the stone with the metal compass and then creates the perfect recess by choosing the right tools.

At the next stop of our tour we arrive in a laboratory: the galvanizing processes take place in the workshop of Andi and Ancsa. Fruzsi usually makes silver jewelry: a piece is included here if a “surface treatment” is needed, for example, if the owner of the jewelry wants to coat the piece with a different colored metal. Or, if the wearer of the silver jewelry has been in a thermal bath and the medicinal water has discolored the jewelry, the object will be treated here. On the counter, we also see two devices that are used before galvanizing: one of them is a tumbler, in which a special cleaning fluid and lots and lots of tiny needles circulate. The other machine, the ultrasonic cleaner, is used to clean more complex forms of jewelry.

Now a silver necklace will get a rose gold plating, and Fruzsi will choose a pair of tiny earrings perpendicular to the earlobe, which the girls will dip into the black ruthenium solution. It is important that the container containing the metallic liquid reaches the correct temperature: if, for example, the ruthenium solution is overheated, the jewelry will turn a bluish tinge, and if the temperature is too low, browning will occur. Andi first cleans the jewelry from dirt in the tumbler and then places the necklace and then the earrings on an anchor bent from copper.

Black ruthenium is a real specialty, this color has recently become very popular among buyers. Just a few minutes and you have a new color and a new character with the previously silverly shimmering jewelry!

Photos: Balázs Mohai

Fruzsi Fekete Jewelry | Facebook | Instagram

In our monthly series, we explore where, how and among what circumstances design products are born. There are cases when a designer creates their object themselves, but many times it takes the joint work of the designer and several manufacturers and subcontractors to provide customers with a flawless item. In each episode, we choose a designer from different fields of design and visit the workshops where the actual work takes place.

Contemporary collage exhibition opens at a unique venue in the Balaton Highlands

Futuristic images of abandoned monuments