Architect Adrienn Veres’ designer attitude is characterized by learning by doing the most. What gives her the greatest joy is creating something with her two hands and if her work has a tangible result in a short time. In addition, she tries to sit in front of the computer as little as possible. The first time she was in FabLab Budapest’s workshop was in December 2018, when she fabricated the tiny elements of an architectural miniature with the help of laser-cutting: she has been a regular user of FabLab since then.

The FabLab Budapest open innovation workshop celebrates the tenth anniversary of its foundation this year. In our mini-series, we ask the users of the workshop about the same five topics. In the latest, and, at the same time, last, episode of our series, we asked Adrienn Veres.

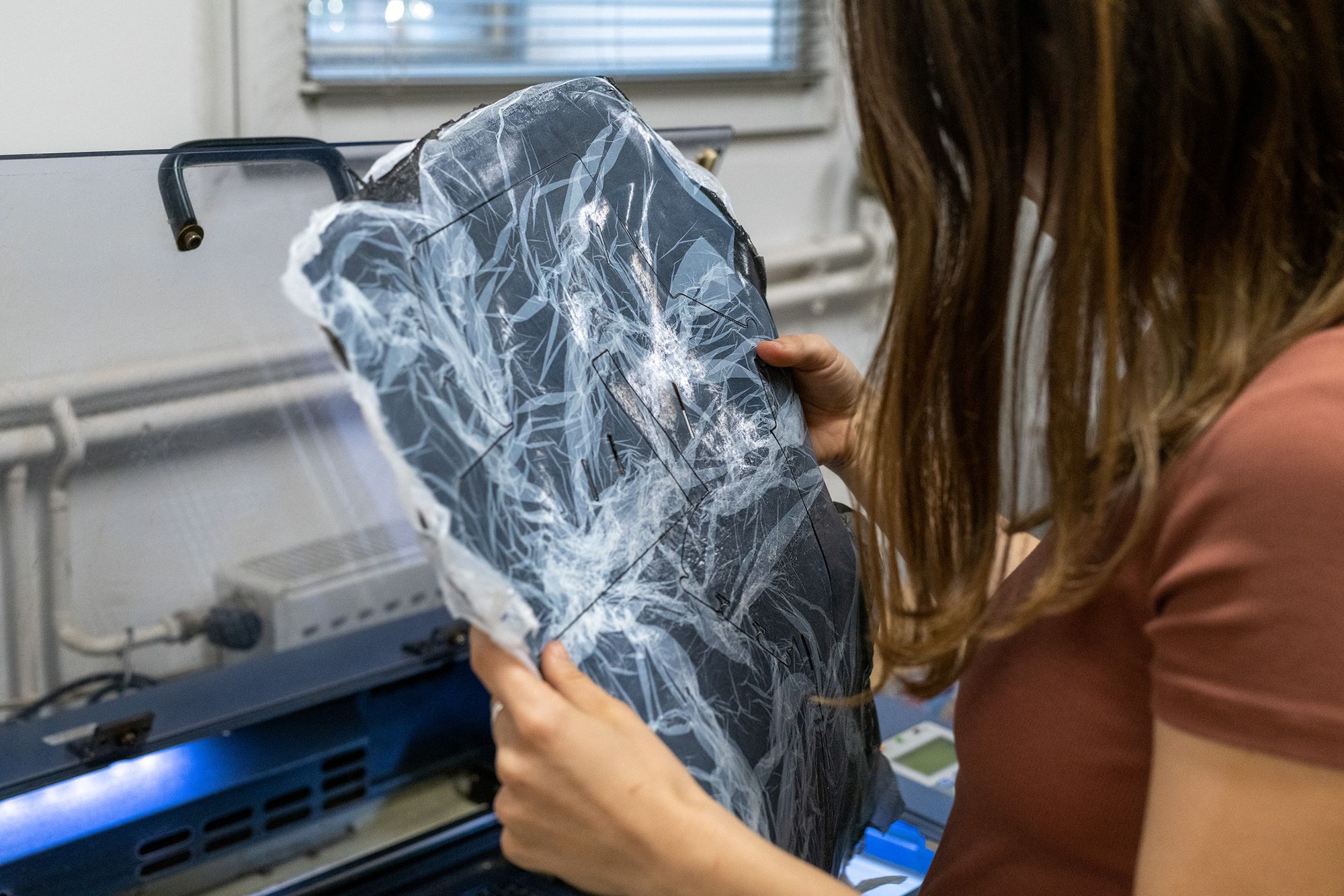

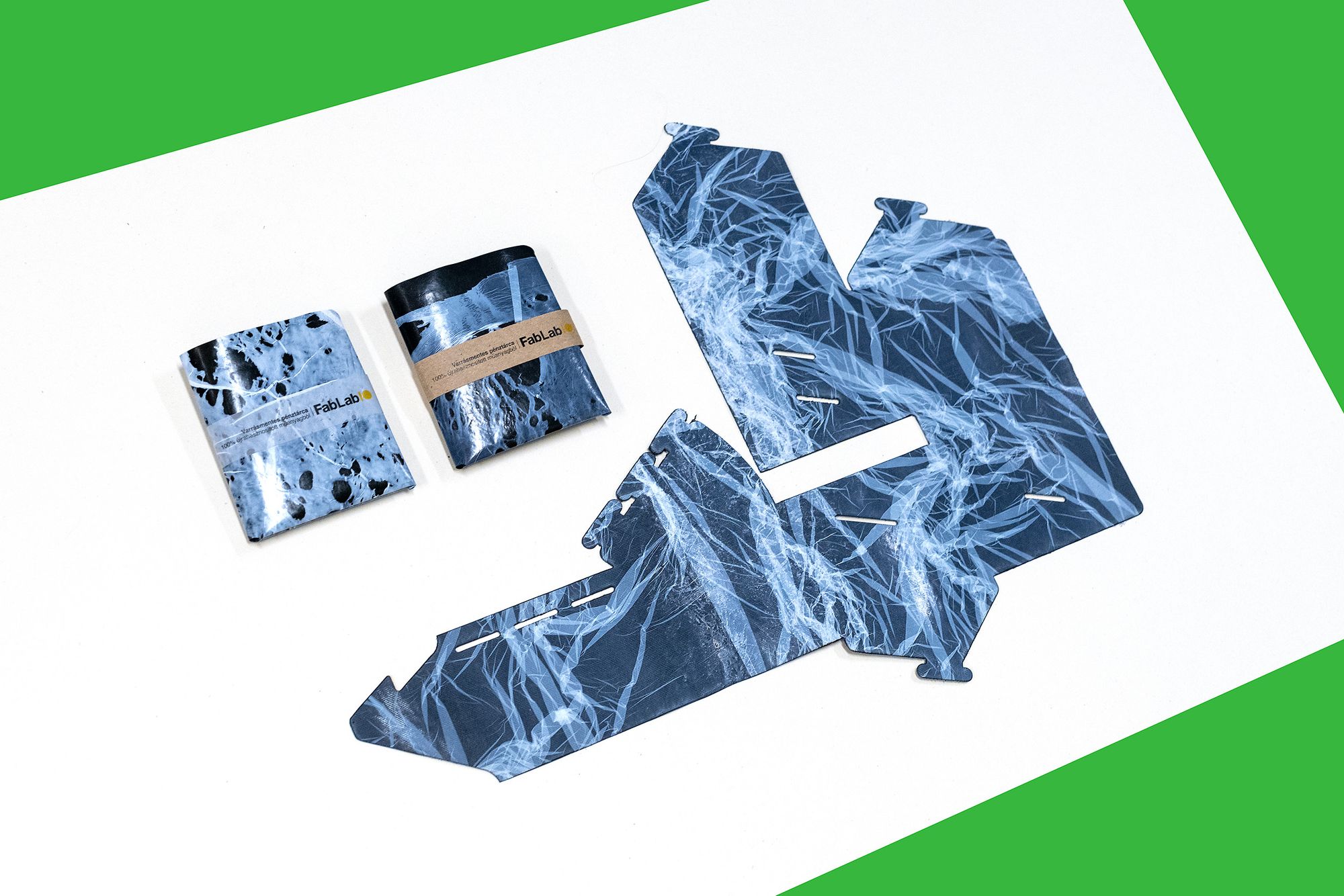

Adrienn is a dedicated fan of plastic recycling, with which she experiments in her workshop shared with Gergely Tasnádi. Their main field of research is to explore local recycling options of general plastic as well as possibilities of using it in architecture and interior design, and the alternative recycling methods of various types of plastic foils and nets. Adrienn is currently working on a furniture collection made of recycled plastic panels only.

OBJECT

Last year, in the framework of the Moholy-Nagy Design Grant, I had the opportunity to design and manufacture a 100% recycled plastic seating furniture. The piece was made of three 600×600 mm HDPE sheets. We cut out the elements of the chair with a CNC milling machine from a 6 mm thin material, and then I bent the cut out elements with a self-built press brake, thus forming the nodes of the furniture. The nodes of the furniture created via bending resulted in a strong structure, thanks to which I could work with thin panels, and so the chair became quite light, with a weight of approximately one kilogram. The chair made of recycled plastic is currently exhibited at the Polish Łódź Design Festival.

FAVORITE TOOL

Most recently, I have used Félix, the CNC milling machine, the most. When designing said piece of furniture, efficient manufacturing was an important aspect: this is why I opted for this technology. After finding the right settings, the manufacturing process was precise and swift, and the machine can work plastic panels of various thickness and size.

ENCOUNTER IN THE WORKSHOP

Dávid’s (FabLab Budapest’s leader—the Ed.) proactive and positive attitude is exemplary and enviable in my opinion. I think he is one of the keys to FabLab’s success. Each project requires a different solution and technology, and Dávid approaches everything with an open mindset and with great expertise. So far I have only met inspiring and kind people in FabLab, and even though I have never worked on a joint project with anyone so far, I hope I will get to do so in the future…

INSPIRATION

FabLab has been a supporter of open source design from the very beginning: this kind of attitude and mindset is close to me, too. Two years ago I got acquainted with recycling via the transparent organization called Precious Plastic operating on open source principles, which has determined and shaped my work ever since. Moreover, thanks to FabLab, I realized that with machines I can implement ideas that I probably could never do with my own bare hands, and on top I also get to save time this way. This realization changed my attitude in a manner that now I take into consideration the opportunities provided by machines right from the early phases of design.

EXPERIMENTATION

In the future, I’d like to continue experimenting with the various recycled plastic films and panels I manufacture. In relation to my furniture project, I am intrigued by the manipulation of plastic’s surface. The unique surface which can be created via CNC milling can be practical for a chair’s seating surface or for a table top, and with the milling of the colorful, layered material, we can create an aesthetically exciting finish.

Photos: Balázs Csizik, Dávid Pap

Adrienn Veres | Instagram

FabLab Budapest | Web | Facebook | Instagram

Water world behind the glass | TOP 5

An island resting on concrete tulips | Heatherwick Studio